The process of manufacturing among most industries depends upon the accurate measurement of gases and fluids. For such purposes, the use of flow meters has been implemented in many small and large-scale production units. These devices work to compute the amount of fluid and gases passing through the pipes. The measurement of pressure enables the engineers to keep a check on the production procedures. In most industrial units, deploying high-performing flow sensors is essential. The pressure of liquids and gases through the pipes is mainly considered as liquid velocity and kinetic energy.

There are several flow meters that serve the needs of industries, especially those that fall under the category of chemicals, petroleum, and food processing. However, the objective of all is similar, but there are many to choose from. So, if you are looking to employ a flow reading device for a specific industrial application, then you should choose as per your particular preferences. You can choose these devices for the below-mentioned purpose, such as:

Monitoring production process

Quality controlling

General research

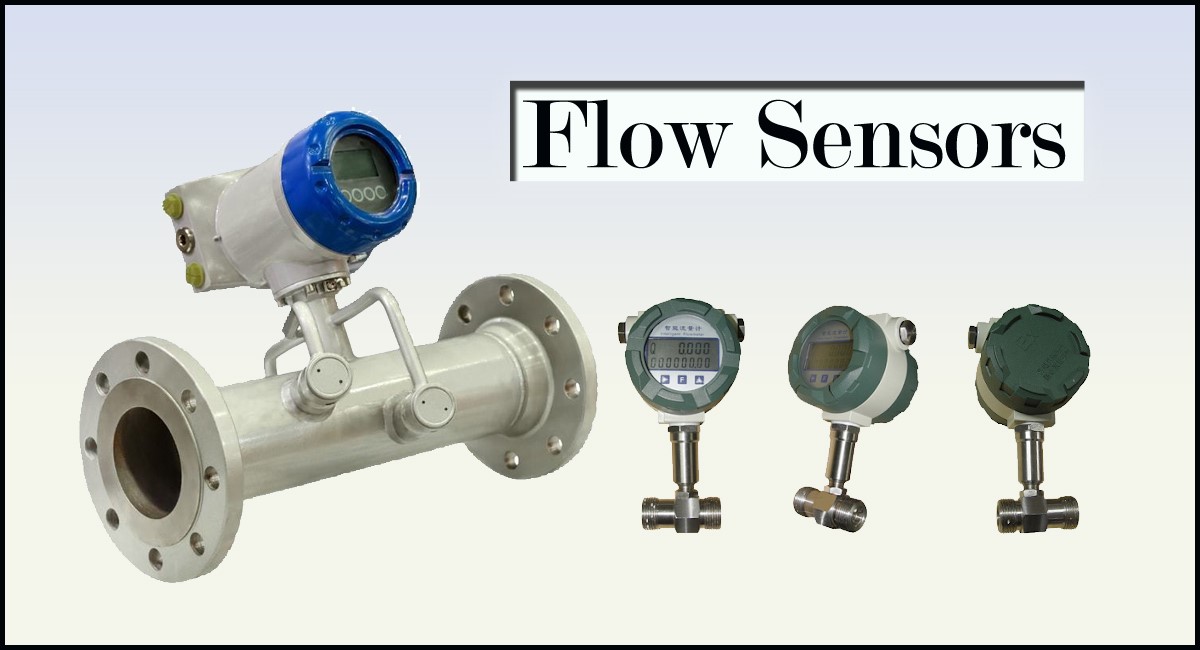

In order to determine the best flow rate sensor, you must take a look at the different varieties available in the market below in this article.

Magnetic flow meter

It is also popularly referred to as a volumetric flow meter. It is primarily a useful industrial application to calculate the flow of liquid flowing into the pipes. The connected electrodes to the pipes enable the users to see the clear rate of flow for water waste and gases. It has the best design that will facilitate you for its use without using any moving parts. The particular feature of this device is really praise-worthy as it can measure the flow with high pressure. You can implement it without any risk of leakage to take the consistent reading for the flow.

Additionally, it can also measure the flow of greasy substances without any glitches. The magnetic flow reader is unaffected by the temperature, density of liquids, and pressure.

Major uses of magnetic flow devices in industrial units are:

Measurement of mud-like substances such as liquid mix cement ash, suspended chemicals, and coal, etc.

Many industrial units require disposing of the heated substance for its safe storage that needs to be measured as well. So, magnetic flow sensors can provide accurate pressure and velocity of heated liquids.

These meters are also helpful in calculating the flow rate of water with accurate pressure. They display the rate on the screen with digital numbers for easy reading and understanding.

Ultrasonic Flow meters

It is another popular category of flow meters used considerably in industrial plants. They are primarily used for evaluating the volume of liquid flow in the pipes. The most suitable application for these meters is at water waste plants where there is a strict need to compute chemical compatibility, and low pressure is required. These meters are also fast to work like magnetic meters and do not include moving parts like mechanical meters. They are easy to maintain at lower costs and deliver high accuracy.

Chief application areas for ultrasonic flow rate sensors are:

They are useful in the applications of dirty liquid measuring and wastewater.

The diverse use of this flow meter makes it unique as it can measure the flowing rate and pressure of liquids as well as gases.

They use ultrasound technology to measure the volume of the flow for gases and water.

Mass Flow meters

As the name suggests, these are the perfect flow sensors that can measure the mass flow of liquids. They are commonly used in the industries that directly engage in the mining process, production of medicines, chemicals and gases, and power, etc. These meters have higher accuracy, and they certainly come with an extensive range to measure the colossal volume of fluids inside the pipes.

Mass flow meters have several features that make them a good choice for many industrial applications. By using these measuring devices, you can get accurate results for the flow, there is no need for inlet and outlet sections, and they can operate without any obstacle for forward and reverse circumstances of the fluid flow inside the pipes.

Benefits of these ultra-modern flow meters in the present industrial settings are:

They require low maintenance that could lead to a significant reduction in the operational cost of industrial plants.

Their working is unaffected by the contaminated substances and deposits inside the fluids.

They have an accurate display of results through the digital screens that provide ease of reading.

They do not require moving parts and work seamlessly.

Give fast response to variation in pressure, volume, and speed of the fluids and gases passes through the pipelines.

The Final Words

The use of flow meter devices has made it easy for industries to streamline the process of manufacturing. These applications are laced with modern features that enable better quality control and monitor the bulk production processes.

Author Bio:

Naman Modi is a Professional Blogger, SEO Expert & Guest blogger at beverlyhillshr.com, He is an Award-Winning Freelancer & Web Entrepreneur helping new entrepreneur’s launches their first successful online business.