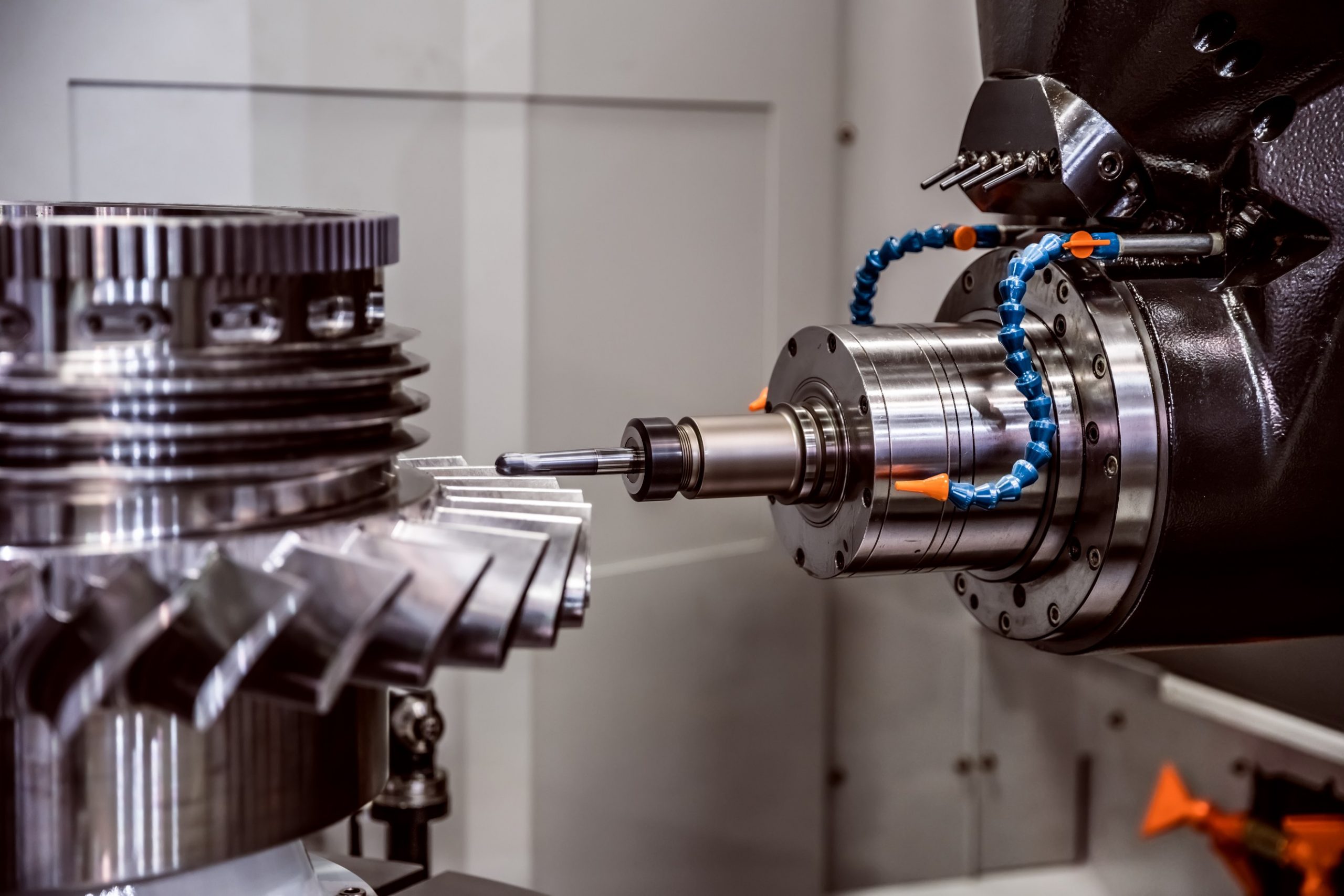

One of the main reasons manufacturing business buys from CNC machine shops in Georgia is that enables their product designers in creating complex products. The CNC machines come in a lot handy in manufacturing the parts, especially those having angles that are difficult to measure manually. However, in addition to these, there are several other benefits of CNC machines as well that will help to improve your manufacturing business.

Eradicate Human Errors

When the products are made manually or with the traditional methods, it is very hard to achieve a level of accuracy and consistency similar to what CNC offers. The CNC machines have different software and tools that help to replicate the products identical to each other. Even the most advanced traditional machines aren’t able to yield these results.

Therefore, we can conclude, in the industries like aerospace, automotive, and medical, where extreme uniformity is required, this is the best option. The CNC machinery for sale is also an effective option for the manufactures that makes complex machine electronics, and want different parts to fit together perfectly.

Speeds up The Process

As with the manual or traditional manufacturing method, you won’t need an engineer to supervise the process at all times. The majority of the CNC machines work automatically without requiring any direct control. Once the instructions and raw materials are added by the manufacturers, it is good to go. This will allow the businesses to replicate the product faster and efficiently. Furthermore, these machines can also work 24/7.

Fewer Resources Needed

Highlighted by Flint Machine, the use of CNC machinery will help businesses to maximize the resources at every development stage. In the beginning, you’ll only need an engineer to digitally make the design and program the mechanism. Once that has been done, the CNC is self-sufficient to carry out the process. Furthermore, it also reduces waste production during the process, while using the raw material only when it’s needed.

Reduces Manufacturing Cost in Long-Run

The reduction in the need for labor and raw materials leads to cost savings as well. This saved-up amount can be used to reinvest and increase production. Or, you can reduce the end price of the product that will give you a competitive edge.

Instead of buying CNC machinery for sale, if you are outsourcing the development to the CNC machinery provider, it also helps in saving the overhead costs. The purchase of software license and the machine, its repair, and hiring staff to supervise the production process will be the responsibility of the manufacturers.

Scale-Up Production

Another advantage of CNC machinery is that it offers various manufacturing options. The production can start at a limited number of high-quality components. And, once there is an increase in the demand for the product, you can scale up the manufacturing. Moreover, that too without compromising on the consistency and quality of the product.

Visit CNC Machine Shops in Georgia for Purchase

These are a few of the ways that CNC machines improve the manufacturing for your business. With the various benefits, we recommend every product designer seriously consider investing in them.