A quintessential symbol of craftsmanship and labor, the humble hammer has been by humanity’s side throughout our long journey of innovation and construction. A pivotal player in the narrative of civilization’s growth. It’s fascinating how this basic tool has been pivotal from ancient times and continues to hold significance today.

The roots of the hammer can be traced back to the ancient Mesopotamians, a civilization known for its pioneering advancements in tools and construction. They crafted rudimentary Hammer types from stone, primarily using them to shape other stones or to chip away at hard surfaces.

As we journeyed through the Bronze and Iron Ages. The hammer metamorphosed, adopting metals into its design and becoming more specialized for various tasks.

Fast forward to today, and we find ourselves amidst a plethora of hammer type, each meticulously designed to cater to specific tasks. From the densely urbanized landscapes of New York to the traditional carpentry shops in Kyoto, the hammer remains an unwavering ally to builders, artisans, and professionals. Its core principle, to apply force onto a surface, has remained remarkably consistent, proving its timeless utility.

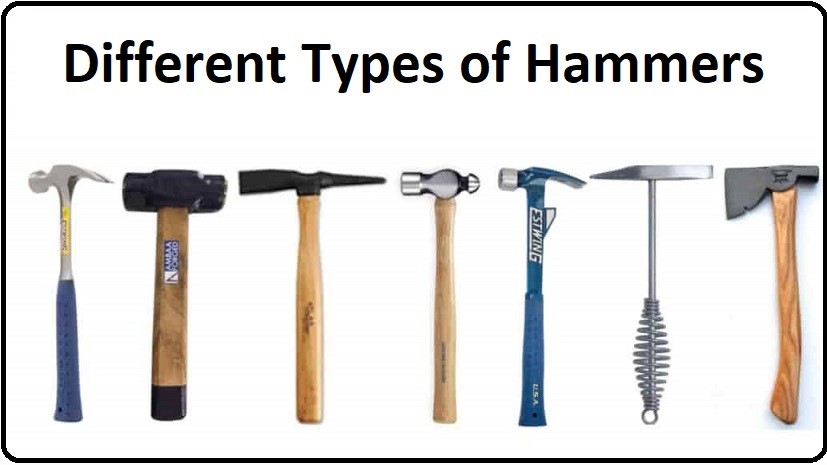

In this article, we embark on a detailed exploration of the myriad hammer type available in today’s market. Delving into their unique features, historical contexts, and optimal use-cases, we aim to equip you with the knowledge to select the perfect hammer for any task at hand.

1. Claw Hammer

The claw hammer’s origins trace back centuries, embodying the essence of human innovation. Its timeless design, while having undergone minor refinements, largely remains consistent with its ancestral versions. A testament to its enduring utility and design brilliance.

The quintessential claw hammer, with its unmistakable curved claw and flat head, often stands as the poster child for hammers in general. Fashioned predominantly from high-quality steel, this tool is an epitome of dual functionality. The hammer’s head is tailor-made for driving nails deep into surfaces with minimal effort, while the curved claw, ingeniously shaped, serves as a reliable nail-puller, making nail extraction seem almost effortless. Its ergonomic handle, often made of wood or fiberglass, ensures a comfortable grip, reducing strain during prolonged use.

Balanced Weight: Typically weighing between 16 to 20 ounces, its balanced weight ensures both power and control in each swing.

Ergonomic Design: The handle’s design, often contoured, reduces the shock transmitted to the user’s hand and wrist. Some modern versions also come with a rubber or vinyl grip for added comfort and slip resistance.

Versatility: Beyond nails, the claw’s design also assists in prying tasks, making it a multifunctional tool in any toolbox.

2. Ball Peen Hammer

The ball peen hammer, sometimes referred to as the “machinist’s hammer,” has origins intertwined with the dawn of metalwork and craftsmanship. As metalsmithing evolved, so did the need for a specialized tool that could shape and work metal without leaving marks, leading to the creation of the ball peen hammer.

The ball peen hammer is distinct in its design. One side flaunts a flat, round face, while the other hosts a rounded ball-like peen. While it might appear simple, the genius is in its specificity. Crafted primarily from hardened steel, the hammer is tough enough to withstand the rigors of metalwork.

Diverse Head Sizes: These hammers come in a variety of weights, allowing for finesse in detailed work or more heft for broader metal shaping.

Shock-absorbing Handles: Modern ball peen hammers often feature handles made from materials like fiberglass or even specially designed metals, absorbing the majority of the shock, thus providing additional comfort during prolonged use.

Durability: Built for the rigorous world of metalwork, these hammers are often drop-forged, ensuring their longevity and ability to resist wear and tear.

3. Sledgehammer

The lineage of the sledgehammer can be traced back to ancient civilizations where rudimentary versions were employed for various heavy-duty tasks. Over time, this tool has evolved into a symbol of raw power and force in the toolkit.

The sledgehammer is the embodiment of brute strength among hammers. It features a massive head, often weighing between 8 to 16 pounds or more, mounted on a long handle. The length of the handle provides leverage and control over the tremendous force that can be generated.

Heft and Power: The sledgehammer’s primary attribute is its weight, making it capable of delivering immense force in a single strike.

Long Handle: The extended handle allows the user to generate substantial momentum and direct it precisely.

Durable Construction: Sledgehammers are designed to withstand intense impact and are typically made from tough materials like steel, fiberglass, or wood.

4. Mallet

The mallet, often considered a gentler counterpart to traditional hammers, has a history deeply rooted in woodworking and craftsmanship. Its evolution parallels the need for more delicate and precise strikes in various trades.

A mallet typically features a head made of wood, rubber, or another soft material. Which sets it apart from traditional hammers with hard, steel heads. The handle can be of various lengths and materials, but it’s often designed for a comfortable grip and precise control. The key characteristic of a mallet is its ability to deliver softer blows, minimizing the risk of damaging the material being struck.

Soft Impact: The mallet’s soft head ensures that it imparts minimal damage to the material it strikes, making it perfect for delicate work.

Weight and Balance: Mallets are design to provide just enough weight to facilitate the task without applying excessive force.

Ergonomic Handle: The handle design often focuses on ergonomic comfort, as mallets are frequently use for extended periods.

5. Framing Hammer

The framing hammer, sometimes referred to as a “builder’s hammer,” has a history tightly woven with the evolution of construction techniques, particularly in the realm of wooden structures. Its design has evolved to cater to the specific needs of framing tasks.

Distinguished by its weight and unique features, the framing hammer is design to tackle the challenges of building wooden structures. It is typically heavier than the average claw hammer, weighing between 20 to 32 ounces.

The hammerhead often features a waffled face to prevent nail slippage, ensuring that every strike counts. Unlike the curved claw of a standard hammer, the framing hammer boasts a straighter claw, which aids in removing nails efficiently.

Weight and Balance: The weight of the framing hammer provides the momentum needed to drive large nails with ease, while its balance ensures control.

Waffled Head: The waffled, textured head minimizes the chances of nails slipping out during strikes.

Straight Claw: The straight claw is ideal for prying and removing nails from wooden structures.

Safety Precautions

No matter the hammer type, safety should always be paramount:

Wear safety glasses to protect against flying debris.

Ensure a firm grip to prevent accidents.

Store in a dry place to avoid rusting and deterioration.

Care and Maintenance

A well-maintained hammer can last generations. Regularly check for loose handles, clean after use, and store appropriately. When working with wood, occasionally rubbing the handle with linseed oil can help prolong its life.

Conclusion

In the realm of tools, hammers stand out as a diverse family, each member designed with a unique purpose and skill set. Whether it’s the humble claw hammer found in every homeowner’s toolkit or the specialized ball peen hammer in a metalworker’s workshop, understanding these various types of hammers is akin to having a comprehensive tool arsenal at your disposal.

The choice of the right hammer is not merely a matter of preference; it’s an essential factor in determining the success and efficiency of a task. Picture using a framing hammer for fine woodworking or a delicate mallet for heavy-duty demolition – it’s an obvious mismatch that could lead to inefficiency, frustration, and even safety risks.

Therefore, knowing your hammers is not just a matter of convenience; it’s a matter of competence. Whether you’re a seasoned professional who wields these tools day in and day out or someone just beginning their DIY journey, the importance of investing in the right tools cannot be overstated.

Furthermore, the evolution of hammers over centuries showcases human ingenuity and adaptability. From ancient civilizations to the modern age, these tools have adapted to meet the changing needs of craftsmen, builders, and artisans. The enduring relevance of hammers is a testament to their utility and time-tested design.

In closing, whether you’re shaping metal with a ball peen hammer, delicately crafting wood with a mallet, or driving nails into a new home’s frame with a framing hammer, there’s a tool designed precisely for your needs. Understanding these tools, their features, and their applications ensures that you can work efficiently, effectively, and safely in various trades and tasks.

As you embark on your next project, remember that the right hammer is more than just a tool; it’s your trusted companion in the world of craftsmanship and construction. Explore a wide range of high-quality hammers and other tools at Business.emechmart to ensure you have the best equipment for your projects.

Author BIO

Ahmad Tunvar

Ahmad Tunvar is the CEO of Business.emechmart which is a prominent place to buy Industrial, Agriculture, Automobile and Building tools online. They are building a platform between the buyers, sellers and the manufacturers, facilitating hassle-free trading of required products and tools.