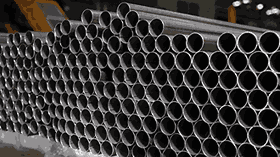

Stainless steel welded pipes have become a cornerstone in various industries due to their exceptional strength, corrosion resistance, and versatility. In this blog, we will delve into the world of stainless steel welded pipes, exploring their production process, key attributes, common applications, and the advantages they offer compared to other materials.

1. The Production Process

Stainless steel welded pipes are created through a multi-step production process. It typically begins with selecting high-quality stainless steel alloys, such as 304, 316, or 316L. These alloys are chosen based on the specific requirements of the end application.

The production process involves the following steps:

A. Coil Selection: Stainless steel coils are chosen based on their thickness, width, and chemical composition. These coils serve as the raw material for pipe production.

B. Uncoiling: The selected coils are uncoiled and fed into the welding machine. This machine is equipped with various welding methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas).

C. Welding: The stainless steel strips are welded longitudinally, creating a continuous tube. The type of welding used can impact the pipe’s quality and performance.

D. Sizing and Shaping: After welding, the tube undergoes a sizing and shaping process to achieve the

desired dimensions.

E. Heat Treatment: Some stainless steel pipes may undergo heat treatment to enhance their mechanical properties, such as strength and corrosion resistance.

2. Key Attributes of Stainless Steel Welded Pipes

Stainless steel welded pipes are prized for several key attributes:

A. Corrosion Resistance: Stainless steel’s inherent resistance to corrosion makes these pipes ideal for applications in aggressive environments, such as chemical processing, marine, and oil and gas industries.

B. Strength and Durability: Stainless steel is renowned for its high strength-to-weight ratio and durability, ensuring the pipes can withstand various mechanical stresses.

C. Hygiene and Cleanliness: Stainless steel is easy to clean and maintain, making it suitable for applications where hygiene is crucial, such as in the food and pharmaceutical industries.

D. Aesthetic Appeal: The shiny and sleek appearance of stainless steel lends an aesthetic appeal to applications in architecture and interior design.

E. Temperature Resistance: Stainless steel pipes can handle extreme temperature variations, making them suitable for high-temperature and cryogenic applications.

3. Common Application

Stainless steel welded pipes are used in various industries, including but not limited to:

A. Construction: Stainless steel pipes are commonly used for structural applications, handrails, and architectural features.

B. Oil and Gas: The corrosion resistance of stainless steel makes it an excellent choice for pipelines, drilling equipment, and refineries.

C. Food and Beverage: Stainless steel’s hygienic properties are vital in the food and beverage industry for processing, storage, and transportation of products.

D. Chemical Processing: Stainless steel is preferred in chemical processing due to its resistance to corrosive chemicals and high temperatures.

E. Automotive: Stainless steel exhaust systems and components benefit from the material’s temperature and corrosion resistance.

4. Advantages Over Other Materials

Stainless steel welded pipes offer several advantages over alternative materials, such as:

A. Corrosion Resistance: They outperform materials like carbon steel, which can corrode in aggressive environments.

B. Durability: Stainless steel pipes have a longer service life than many other materials, reducing maintenance and replacement costs.

C. Hygiene: In applications requiring cleanliness and hygiene, stainless steel is superior to materials like plastic.

D. Temperature Range: Stainless steel’s ability to handle extreme temperatures surpasses that of materials like PVC.

Conclusion

Stainless steel welded pipes are versatile and reliable components that have become indispensable in various industries. Their unique combination of strength, corrosion resistance, and aesthetics has solidified their position as a top choice for countless applications. Whether you’re involved in construction, oil and gas, food processing, or any other industry, stainless steel welded pipes will likely play a critical role in your operations, ensuring longevity, safety, and performance.