There has been a rise in the amount of attention that is being directed against the production of meat in our contemporary environment, which is characterized by worries regarding the safety of food and sustainability. Consumers are becoming more and more interested in learning about the origins of their food and the processes that are used to create it, from the farm to the table. Several less well-known factors shed light on the complexities of ensuring that meat is safe to consume, even though many people are aware of the fundamental principles of safe meat production. Three things about the manufacture of safe meat that you might not be aware of are as follows:

Pre-Harvest Food Safety Interventions

After-harvest treatments, such as cooking or processing processes, are typically the subject of the majority of conversations concerning the safety of meat. Nevertheless, the events that take place before the animal arrives at the processing plant are of equal importance. Food safety measures that are undertaken on farms to reduce the likelihood of microbial contamination in animals before their slaughter are referred to as pre-harvest food safety treatments. To promote gut health and reduce the predominance of dangerous bacteria, these treatments include proper animal care, immunization programs, biosecurity measures, and the utilization of feed additives such as probiotics or prebiotics. In addition, technological breakthroughs in genetics and selective breeding techniques are being investigated to generate livestock that have inherent resistance to infections, which would further improve the safety of food before it is harvested.

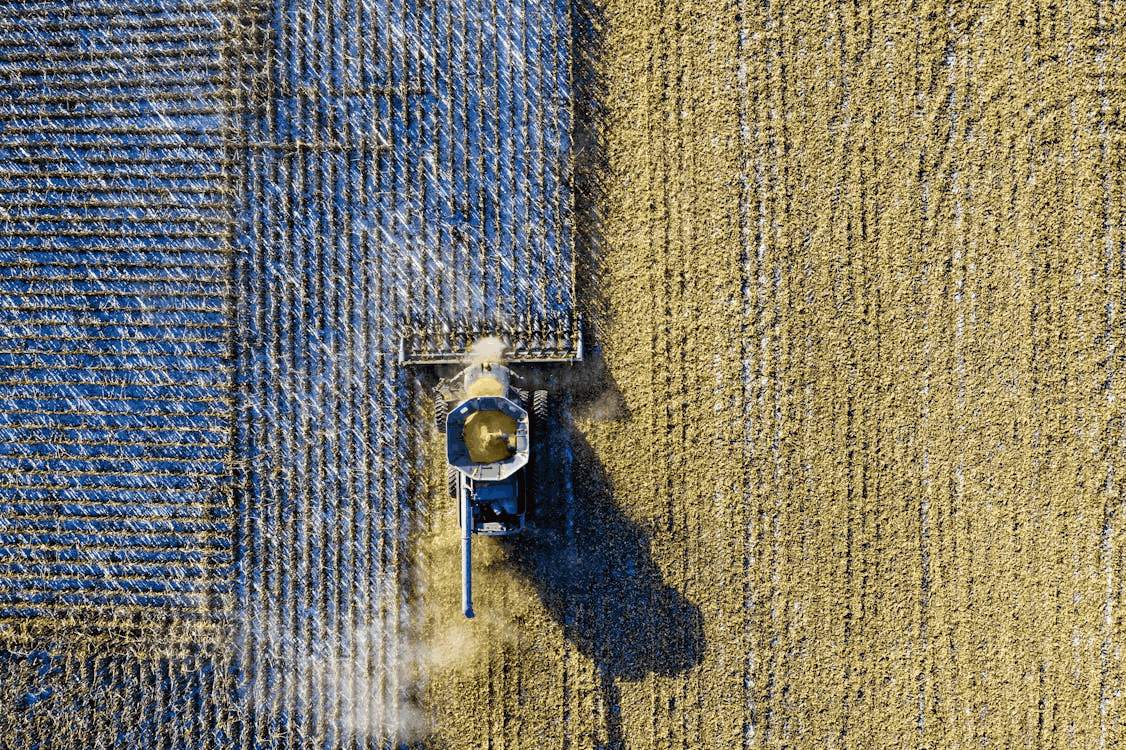

Different Types Of Equipment Used For Processing

In industrial food processing, the manufacture of food products is on a large scale through the utilization of specialized technology and equipment. To transform raw materials into final products, this process includes several processes, including cleaning, sorting, cutting, mixing, cooking, packaging, and labeling. Several issues, including efficiency, guaranteeing consistency in quality and size, keeping safety requirements, preserving freshness through technologies such as refrigeration and pasteurization, and scaling production to meet market demand, all contribute to the necessity of equipment. As a food manufacturer, you need to optimize your operations and efficiently offer high-quality products on a wide scale. Manufacturing machinery on an industrial scale is specifically intended to manage large quantities of food production efficiently. By investing in automated machinery such as industrial food processing equipment, you can accomplish repetitive activities in a short amount of time, which reduces the amount of time needed for manufacturing as well as the expenses associated with the workforce.

Traceability Technology

To assure the safety and transparency of the meat supply chain, traceability is of the utmost importance. The process of tracking meat from the farm to the consumer’s plate has been completely transformed with the introduction of cutting-edge traceability technology such as blockchain and RFID (Radio-Frequency Identification). The technology known as blockchain makes it possible to create an immutable digital ledger that records every transaction and movement of beef products across the supply chain. Consumers are provided with unparalleled visibility into the origin and travel of their meat, as each step, beginning with the farm where the animal was raised and continuing through the processing plant and distribution hub, is logged in real-time. RFID tags, which are inscribed with one-of-a-kind identification codes, make it possible to track and trace individual animals and meat products seamlessly. If there is a problem with food safety or an outbreak of contamination, this improved traceability makes it possible to conduct recalls that are both prompt and targeted, thereby reducing the negative impact on public health and consumer confidence.

Conclusion

The production of safe meat is a multi-step process that begins with pre-harvest interventions, continues with the systematic need for equipment, and culminates with the implementation of modern technology for traceability. By gaining a grasp of and putting into practice these less well-known areas of meat safety, producers can maintain the highest standards of quality and integrity, preserving the confidence of consumers and contributing to the protection of public health. Being aware of these methods gives you the ability to make educated decisions about the meat products you consume, so contributing to a food system that is both safer and more environmentally beneficial.