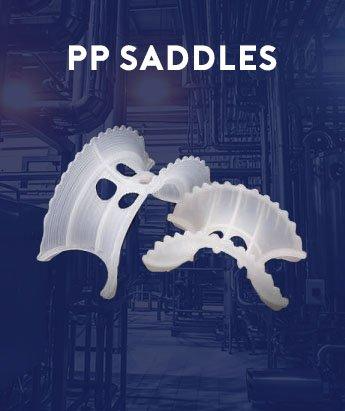

Polypropylene (PP) saddles have emerged as a versatile solution in various industrial applications, offering a range of benefits that make them indispensable in processes across different sectors. As a leading PP saddles supplier in India, it’s crucial to understand the advantages these components bring to the table. In this article, we’ll delve into the top two benefits of using PP saddles, shedding light on why they are favored in diverse applications.

1. Chemical Resistance:

One of the standout features of PP saddles is their exceptional chemical resistance. This characteristic makes them ideal for use in industries where exposure to corrosive substances is a constant challenge. Whether it’s in the petrochemical sector, wastewater treatment plants, or chemical processing facilities, PP saddles demonstrate remarkable resistance to a wide range of acids, alkalis, and organic solvents.

The molecular structure of polypropylene imparts a high level of inertness, preventing chemical reactions that could compromise the integrity of the saddles. This resistance ensures longevity and reliability, even in harsh operating conditions. As a result, industries can rely on PP saddles to maintain efficiency and productivity without worrying about deterioration due to chemical exposure.

Moreover, PP saddles offer resistance to corrosion, rust, and degradation, further enhancing their suitability for demanding environments. This resilience translates to cost savings for businesses, as they experience reduced downtime and maintenance costs associated with equipment failure or deterioration.

2. Thermal Stability:

Another key benefit of PP saddles is their impressive thermal stability. In industries where processes involve high temperatures, such as distillation, absorption, or stripping operations, maintaining the integrity of equipment components is paramount. PP saddles excel in such scenarios, retaining their structural integrity and performance even at elevated temperatures.

The thermal properties of polypropylene allow PP saddles to withstand a wide range of operating temperatures without undergoing deformation or degradation. This stability ensures consistent performance over extended periods, contributing to process efficiency and reliability.

Furthermore, PP saddles exhibit low thermal conductivity, which helps in minimizing heat transfer within the system. This characteristic is particularly advantageous in applications where temperature control is critical, as it enables precise regulation of process parameters.

Conclusion:

In conclusion, the use of PP saddles offers significant advantages across various industrial applications. As a leading PP saddles supplier in India, understanding these benefits is essential for catering to the diverse needs of customers across different sectors.

From their exceptional chemical resistance to impressive thermal stability, PP saddles provide a reliable solution for challenging environments where durability and performance are non-negotiable. By leveraging the unique properties of polypropylene, industries can enhance operational efficiency, reduce maintenance costs, and ensure the longevity of their equipment.

As the demand for high-quality components continues to rise, PP saddles stand out as a versatile and cost-effective solution that unlocks numerous advantages for businesses across India and beyond. Embracing the benefits of PP saddles is not just a choice; it’s a strategic investment in the success and sustainability of industrial processes.