If you’re considering making a logo or design for your company, you might be considering T Shirt screen printing Portland Oregon. Screen printing involves the use of real screens, which need to be cut and then spread with ink. In order to get quality results, screen printing and vinyl printing are two options. Screen printing requires more effort than vinyl printing, but the results are worth it. Read on to find out more about these two options.

Pros of T Shirt Screen Printing

There are many benefits of screen printing T-shirts. First, the ink used doesn’t penetrate the fabric, resulting in intense colours on darker fabrics. Second, the ink is relatively easy to reproduce, as a stencil can be used multiple times. Third, screen printing is inexpensive, since you can get several T-shirts printed with just one order. In addition, screen printing near me also produces limited color options for a design. Fourth, you can get multiple-colour printing by simply adding more than one colour to a design.

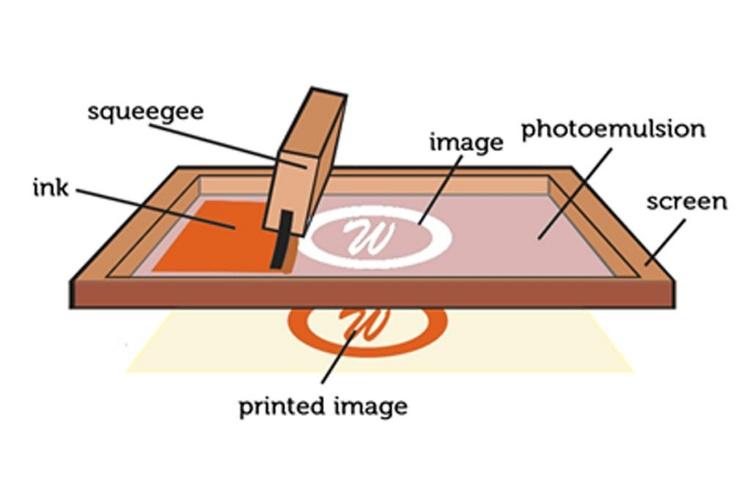

Lastly, screen printing is more affordable than traditional methods. If you plan to order a large quantity of T-shirts, screen printing may be the best option for you. However, if you’re only printing a few, it could take you several days to complete the job. Screen printing, also known as silk screening, uses a mesh to transfer the ink onto a T-shirt. Once the image is transferred to the t-shirt, a professional screen printer can start the printing process.

T-shirt screen printing is an excellent way to promote your business. While the cost of this method may be high, the end result will be worth it. In addition to creating high-quality designs, screen printing is the most affordable way to advertise. It also allows smaller organizations to spend more on their advertising budgets. A good screen printing t-shirt company will be able to help you get the right results for your specific needs.

Need to register colors by hand

When screen printing t-shirts, the registration process is critical to achieving perfect prints. Registration is a process of aligning a number of screens to produce a print with different colors. Getting the registration correct is critical to getting great prints and avoiding t-shirt memes. Below is a step-by-step guide for screen printing t-shirts:

Screen printing ink is most commonly made from Plastisol, which is widely available in North America. While some companies use additives for a softer finish, good technique and a thorough understanding of the variables are still essential to producing a quality print. Ink can either be pressed into the fibers of the shirt or be put directly on the screen. If the screen is too thick or too thin, it is best to use a guiding laser for more precise registration.

Screen printing costs depend on the number of colours you want to print and the fabric’s price per unit. The process is versatile and can be used for any fabric, including t-shirts, hoodies, jackets, fleece, and more. It is also an inexpensive and convenient way to produce custom clothing. And it doesn’t require a large minimum order. In addition, screen printing is available for all fabrics – even synthetic materials. However, when screen printing t-shirts, it is important to use a stencil to get a perfect colour match.

Need to heat cure graphic

The first step in the screen printing process is to align the design to ensure it’s in the proper position. After lining the design up, the squeegee (a rubber edged hand held blade) will push the ink through the mesh of the screen and onto the T-shirt. If you want the design to appear crisp and clear, this step is essential. After this step, you will want to heat cure the design to ensure the ink dries evenly on the canvas.

Screen printing inks must be heat-cured to protect the finished product. The standard Plastisol inks cure at 320 degrees, while low-bleed inks are cured at temperatures below that. If the ink is not heat-cured correctly, it may stain the shirt and cause cracks. To combat this, screen printing ink manufacturers have created low-bleed inks that cure at lower temperatures.

In addition to keeping the graphic in the correct color, heat-curing a T-shirt is crucial to keeping the print on the T-shirt from fading. Properly curing your T-shirt will prevent it from cracking and fading while washing, as the ink will need to reach a certain temperature to bond to the fabric. Different types of ink require different curing temperatures. To get the most vibrant colors from your design, you should apply a high-quality, environmentally friendly ink.