In the realm of electromechanical systems, noise stands as a persistent challenge. Whether it’s in industrial machinery, household appliances, or automotive applications, excessive noise generated by motors can lead to discomfort, decreased efficiency, and even safety concerns. Fortunately, advancements in magnetic assemblies offer promising solutions to mitigate this issue, enhancing both performance and user experience.

Understanding Noise

Motor noise primarily stems from the interaction between electromagnetic forces and mechanical components within the motor. These forces induce vibrations and mechanical resonances, producing audible sound waves. Factors such as motor design, operating conditions, and surrounding environment influence the intensity and frequency characteristics of the noise generated.

The Role of Magnetic Assemblies

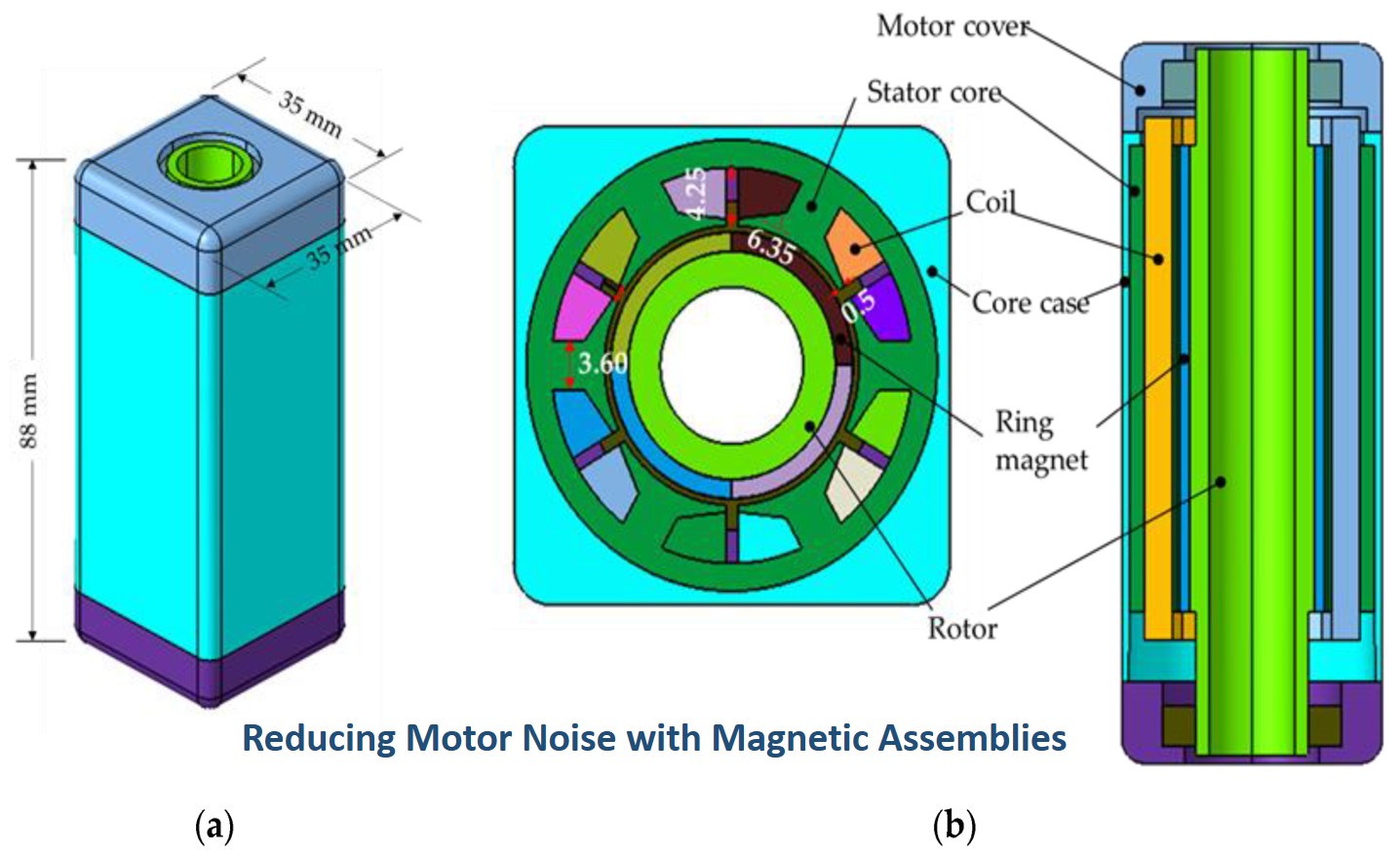

Magnetic assemblies play a pivotal role in motor performance and noise reduction. They comprise a combination of permanent magnets, soft magnetic materials, and sometimes electromagnets, strategically arranged to control the magnetic field distribution within the motor. By optimizing this magnetic field, engineers can minimize undesirable effects like cogging torque and electromagnetic interference (EMI), both of which contribute significantly to noise.

Cogging Torque Reduction

Cogging torque, also known as detent torque, refers to the reluctance of a motor to start rotating from a standstill position due to the interaction between the permanent magnets and the magnetic field of the motor’s stator. Magnetic assembly can be designed to mitigate cogging torque by carefully shaping the magnetic field profile, resulting in smoother motor operation and reduced audible noise during startup and low-speed operation.

EMI Suppression

Electromagnetic interference (EMI) occurs when the electromagnetic fields generated by a motor interfere with nearby electronic devices, leading to performance degradation or malfunction. assemblies equipped with proper shielding and field shaping techniques can effectively suppress EMI, ensuring compliance with regulatory standards and minimizing potential sources of noise pollution in sensitive environments.

Advanced Materials and Design Techniques

Recent advancements in materials science and manufacturing technologies have enabled the development of assemblies with enhanced performance and versatility. For instance, the utilization of rare-earth magnets such as neodymium and samarium-cobalt allows for stronger magnetic fields in compact form factors, facilitating the design of more efficient and quieter motors. Additionally, computer-aided design (CAD) software and finite element analysis (FEA) tools enable engineers to optimize the geometry and configuration of assemblies for specific applications, further reducing noise and improving overall motor performance.

Introducing MQI Technology

One noteworthy example of innovative magnetic assembly technology is MQI (Magnetic Quiet Innovation) Technology. Developed by leading manufacturers in collaboration with research institutions, MQI Technology employs advanced magnet materials, precision engineering, and proprietary design algorithms to achieve unparalleled levels of noise reduction in motors across various industries. By harnessing the power of assemblies, MQI Technology delivers quieter, more efficient, and more reliable electromechanical systems, setting new standards for performance and user experience.

Conclusion

In conclusion, assemblies play a crucial role in mitigating motor noise and enhancing overall system performance. By carefully designing and optimizing magnetic field distributions, engineers can minimize cogging torque, suppress EMI, and improve the efficiency of electromechanical systems across a wide range of applications. With continued innovation and the adoption of technologies like MQI, the future promises quieter, more efficient, and more comfortable motor-driven devices for consumers and industries alike.