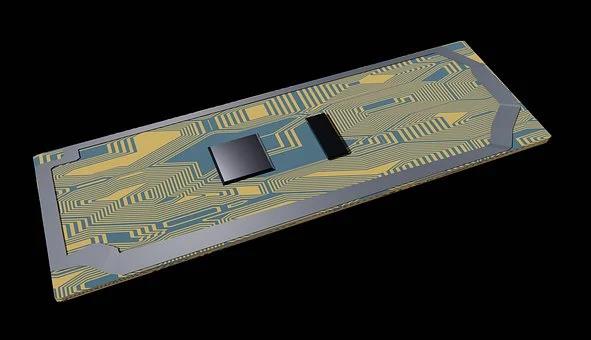

Printed Circuit Boards today are minute, multidimensional, and intricate systems that are being produced at record speeds. The sophisticated design software and PCB manufacturing processes don’t bear any resemblance to the first PCB patented by the renowned engineer Paul Eisler in 1943. So, what has changed between 1943-2020? Well, pretty much everything.

As consumer demand for more technologically advanced devices and equipment grows, so does the need for more efficient PCBs. PCBs are the foundational basis of all electronic devices, so the intense pressure for advancements that PCB manufacturers and repairers face every year is understandable.

As more electronics consumers drive the demand for slimmer and faster-functioning devices, industry professionals must also seek to improve their manufacturing and repair processes. Here are some industry trends that PCB repair and manufacturing experts expect to impact the industry in the years to come –

Industry Growth

The growth of the PCB industry isn’t really a new trend. In 1995, the 52-year old PCB market crossed the $7 billion valuation for the first time. By the end of 2021, the global PCB market is expected to be valued at $73.8 billion. Given that the entire electronic world runs on PCBs, a $100 billion valuation might be sooner than we expect.

IT Rush

The term ‘Information Technology’ is used to denote all the technologies involved in the processing and managing data. PCBs are fundamental to the Information Technology industry. Over the next decade, global industries will witness the rollout of a new generation of Information Technology devices. Major changes are expected in the public telecommunication sector and the IoT sector (Internet of Things).

So, expect to hear terms like flat panel displays and PCBs for cloud computing more frequently over the next decade as PCBs will need to evolve to stay compatible with this upcoming generation of Information Technology and its new requirements. Industry Focus will be on highly reliable PCBs that guarantee long shelf-lives of electronic products.

All electronic components, especially PCBs, will also need to be easily repairable and reworkable. The days of scrapping devices and manufacturing projects over small component errors are gone. Providers of the best PCB repair services are already gearing up to help manufacturing companies deal with frequent engineering change orders (ECOs), product upgrades, reworks, etc.

Manufacturers must either have large-scale teams of IPC-certified PCB repair experts. Or they can drastically cut costs by outsourcing these tasks to PCB repair experts. Either way, they’ll have to prepare to make the components they use easily reworkable and repairable as the leading OEMs are already doing so.

The Rise of Flexible PCBs

Think the growth of the PCB industry from $7 billion in 1995 to $73.8 billion in 2021 was impressive? Then, the growth of the flexible PCB sector will amaze you. Valued at just $15.2 billion in 2020, the flexible PCB market is set to reach a $27 billion valuation by 2022!

That’s because flexible electronics are in demand. This high demand for flexible technology is making flexible PCBs the speediest growing segment of the global PCB industry. In fact, flexible PCB technology is expected to overtake rigid PCBs when it comes to sales growth very soon.

The reason behind the high demand for flexible PCBs lies in the word ‘flexible.’ Due to their flexibility, these PCBs can handle any amount of stress, even if users bend them a hundred times. Flexible PCBs are inherently light, bendy, super-thin, and very easy to manufacture.

The industries behind this trend of flexible PCBs include –

- Medical Devices: Medical devices need to innovate faster than any electronic devices. Flexible PCBs allow important medical devices to be smaller and more flexible. The compact circuitries on flexible substrates enable medical device manufacturers to create devices like implantable heart monitors, surgical sensors, etc.

- Environmental Friendliness: There’s no global ‘environmental industry,’ but the effects that advocates for the environment have on the PCB industry cannot be underestimated. Initiatives like making lead-free PCBs or manufacturing more reworkable PCBs have all been triggered by the demand for the electronics industry to be more environmentally friendly. Flexible PCBs are much more reliable than rigid PCBs. Hence, equipment with flexible PCBs is less likely to contribute to large-scale equipment scrappages. They’re also biocompatible and don’t negatively affect human tissues when implanted in our bodies.

- LED Lighting: LED strip lighting depends on flexible PCBs.

- Wearable Technology: Wearable electronic devices have a market valuation of over $30 billion. These devices are constantly dropped, shaken, bent, etc., by users. So, flexible PCBs that can handle such shocks and vibrations are very important for the wearables industry.

Other common trends include – the rise in demand for high-density PCBs, PCBs with higher frequencies, and PCBs with higher thermal conductivity rates. PCB technology keeps advancing as market priorities change.

All companies and manufacturers that and invest in new technologies must be aware of these changing trends. They must also partner with reliable PCB rework and repair specialists who can help them navigate this exciting future in the best way possible!