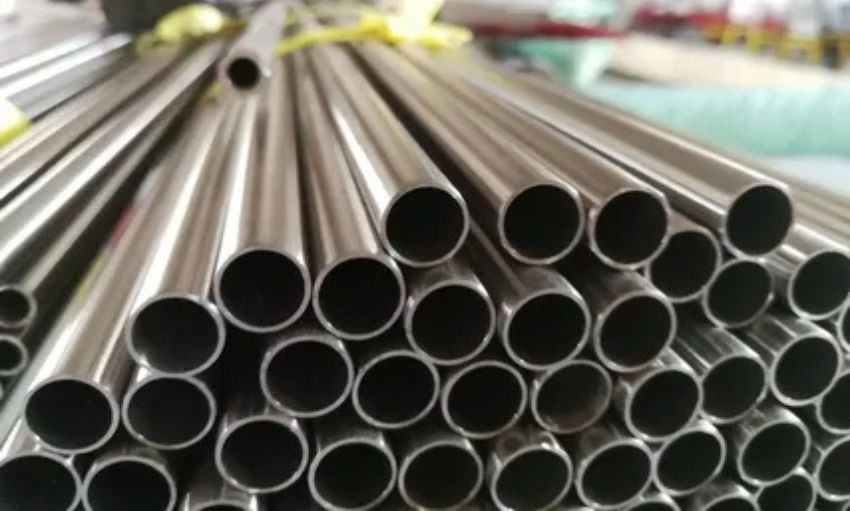

Stainless steel pipe refers to the hollow cylindrical structure that is made up of stainless steel materials, used to convey fluids, gases, and/or solids. Also, stainless steel pipes do not corrode or scale as compared to the materials that are made up of carbon steel.

Such pipes find many applications in the “oil and gas industry,” “chemical processing,” “water treatment,” “pharmaceutical sector,” “food and beverage sector,” and “construction sector.”

Why Stainless Steel Pipes Are Special

The main advantage of stainless steel pipes is corrosion resistance. Chromium in the steel forms a thin oxide layer that protects the surface from rust and scratches. This layer is self-repairing, which ensures long-term durability even in harsh conditions.

Other benefits include:

- High mechanical strength

- Smooth internal surface for efficient flow

- Ability to handle extreme temperatures

- Low maintenance and long service life

Classification of Stainless Steel Pipes by Alloy Grade

Stainless steel pipes can be classified based on the alloy grade, which determines their strength, corrosion resistance, and suitability for different environments.

1. Austenitic Pipes

- Grades: 304, 304L, 316, 316L

- Non-magnetic, excellent corrosion resistance, easy to fabricate

- Applications: chemical plants, food processing, pharmaceuticals

2. Ferritic Pipes

- Grades: 409, 430

- Magnetic, moderate corrosion resistance, lower cost

- Applications: automotive exhaust systems, industrial equipment

3. Martensitic Pipes

- Grades: 410, 420

- Heat-treatable, strong and wear-resistant, moderate corrosion resistance

- Applications: valves, shafts, mechanical components

4. Duplex and Super Duplex Pipes

- Grades: 2205, 2507

- High strength, excellent resistance to stress corrosion cracking

- Applications: offshore platforms, chemical and petrochemical plants

Standards and Specifications of Stainless Steel Pipes

Stainless steel pipes are manufactured according to global standards to ensure quality and performance:

1. ASTM A312 Pipes

- Seamless and welded austenitic stainless steel pipes

- Suitable for high-temperature and pressure applications

- Widely used in chemical, petrochemical, and food industries

2. ASTM A790 Pipes

- Seamless and welded duplex stainless steel pipes

- Combines high strength and corrosion resistance

3. ASTM A928 Pipes

- Super duplex stainless steel pipes

- Ideal for highly corrosive and aggressive environments like offshore oil rigs

Types of Stainless Steel Pipes by Manufacturing Process

1. Seamless Pipes

- Made from solid billets, no welding involved

- Stronger and withstands high pressure

- Common in oil, gas, and chemical pipelines

2. Welded Pipes

- Made by rolling and welding steel sheets or strips

- Cost-effective, suitable for low to medium pressure

- Used in water supply, structural, and decorative applications

Application-Based Types of Stainless Steel Pipes

Stainless steel pipes can also be classified based on the end-use application.

1. Sanitary Pipes

- Smooth internal finish for hygienic applications

- Used in food, dairy, beverage, and pharmaceutical industries

2. Mechanical Pipes

- Stronger pipes for structural or mechanical systems

- Used in heavy equipment, construction, and industrial applications

3. Polished Pipes

- Pipes with a polished exterior for aesthetics or easy cleaning

- Common in architectural structures, decorative projects, and high-end sanitary systems

How to Choose the Right Stainless Steel Pipe

When selecting a stainless steel pipe, consider:

- Alloy grade and corrosion resistance requirements

- Pressure and temperature conditions

- Environmental exposure (offshore, chemical, or indoor use)

- End-use application (sanitary, mechanical, or polished)

- Compliance with international standards like ASTM, ASME, or ISO

Choosing the correct grade and type ensures long-term durability, efficiency, and safety.

Conclusion

Stainless steel pipes are indispensable in modern industry due to their corrosion resistance, strength, and versatility. Understanding the types based on alloy grade, standards, and applications helps engineers and procurement specialists select the right pipes for their systems. From seamless high-pressure pipelines to polished sanitary pipes, stainless steel offers reliable performance across a wide range of demanding environments.