What is the operation of a waterjet cutting machine? This is the question many manufacturers, engineers, and buyers ask when searching for a specific and exact cutting technique.. Waterjet cutting is a state-of-the-art technology, which involves the use of very high-pressure water and in some cases, water mixed with abrasive particles to cut various types of materials precisely.

It is a cold-cutting process, hence does not create any heat or cause any damage to the material. This makes waterjet cutting applicable to industries such as aerospace, automotive, stone, glass and food processing. In this manual, we describe how a waterjet cutting machine operates and why it finds extensive application in the contemporary world of manufacturing.

What Is a Waterjet Cutting Machine?

A waterjet cutting machine refers to a cutting machine used in industry for cutting materials using a high-velocity stream of water, with or without abrasives, without heat.

Pure Waterjet vs Abrasive Waterjet Cutting

- Waterjet cutting is pure, and only water is required; it is best suited for soft materials.

- Garnet abrasives are combined with abrasive waterjet cutting to cut hard and thick materials.

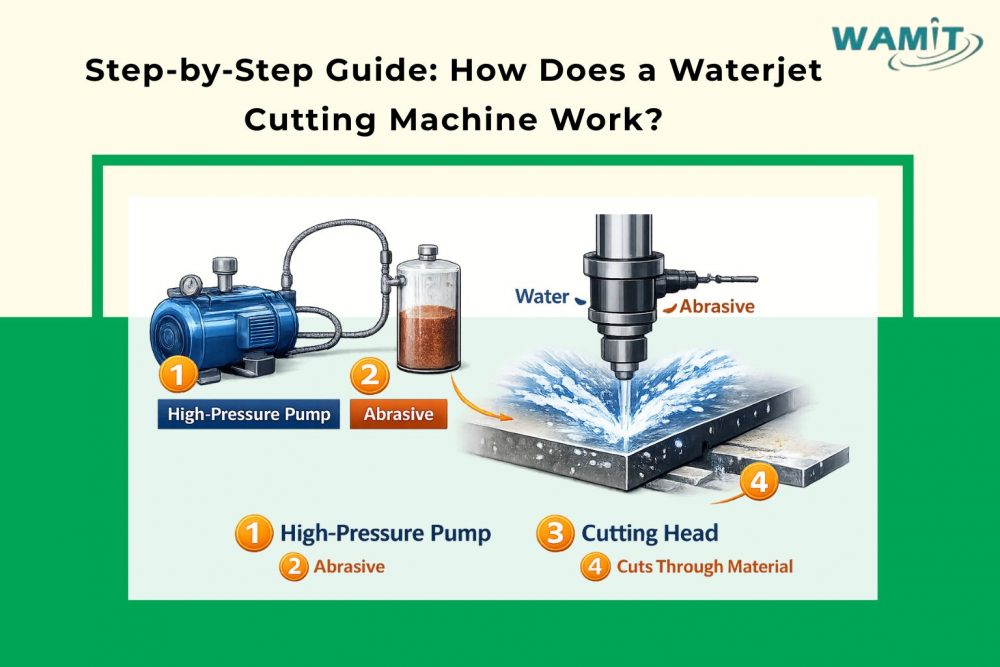

Step-by-Step Process: How Waterjet Cutting Works

Understanding the working process helps clarify how a waterjet cutting machine works in real-world manufacturing environments.

Step 1 – Water Pressurization

The pump that pressurizes the water is an ultra-high-pressure pump, usually between 30,000 and 90,000 PSI. This high pressure turns normal water into a high cutting tool.

Step 2 – Water Acceleration Through the Orifice

The pressurized water is directed through a small hole, which transforms the pressure into velocity. The resulting stream of water flows at a speed that is almost three times the speed of sound forming the cutting force.

Step 3 – Abrasive Injection (For Abrasive Waterjet Cutting)

In the case of hard materials, the abrasives like garnet are sprayed into the water stream. They enhance cutting power and enable the machine to cut through metals, stone and composite materials.

Step 4 – Material Cutting & Erosion

Waterjet cutting is performed by micro-erosion rather than melting. The high-energy stream continuously erodes the material and provides clean edges without thermal damage.

Step 5 – CNC-Controlled Movement

A CNC (Computer Numerical Control) system guides the cutting head along precise paths. This enables:

- Complex shapes

- Tight tolerances

- High repeatability

Step 6 – Slug Removal & Water Catcher Tank

The cut material falls into a water catcher tank, which absorbs energy, reduces noise, and improves operator safety.

Key Components of a Waterjet Cutting Machine

A waterjet cutting machine has various parts that work together to cut materials accurately and smoothly.

High-Pressure Pump System

The pump is the heart of the system, responsible for generating cutting pressure.

- Intensifier pumps: High pressure, heavy-duty use

- Direct drive pumps: Energy-efficient and quieter operation

Water Filtration & Conditioning System

Clean water prevents nozzle wear and ensures consistent cutting quality. Impurities can significantly reduce machine life.

Cutting Head & Nozzle Assembly

Key elements include:

- Orifice

- Mixing chamber

- Focusing tube

These components shape and direct the cutting stream.

Abrasive Delivery System

Garnet abrasives are used in most machines, with the flow rate controlled to balance the speed of cutting and the cost.

CNC Controller & Motion System

The CNC system ensures accuracy, path optimization, and automation for industrial production.

Types of Waterjet Cutting Machines

There are different types of waterjet cutting machines,and each type is used for specific cutting applications.

Pure Waterjet Cutting Machines

Best for:

- Rubber

- Foam

- Textiles

- Food products

Abrasive Waterjet Cutting Machines

Used for:

- Metals

- Glass

- Stone

- Ceramics

3-Axis vs 5-Axis Waterjet Systems

- 3-Axis: Flat cutting

- 5-Axis: Bevel cuts and complex geometries, common in aerospace and automotive industries

Materials That Can Be Cut Using Waterjet Technology

Waterjet cutting can be used to cut many types of materials, from soft materials to hard metals.

Metals

- Steel

- Aluminum

- Titanium

- Copper

Non-Metals

- Glass

- Stone

- Plastics

- Rubber

- Composites

Heat-Sensitive & Exotic Materials

Because there is no heat-affected zone, waterjet cutting is ideal for delicate or high-value materials.

Advantages of Waterjet Cutting Machines

Waterjet cutting machines have numerous advantages that include clean cuts and zero heat damage.

- No heat-affected zone due to cold cutting.

- Great accuracy and sharp edges.

- Minimal material waste

- Capability of cutting nearly all materials.

- Environmentally friendly process.

In manufacturing companies that require efficiency, waterjet cutting machines provide superior performance in industries.

Limitations of Waterjet Cutting

While powerful, waterjet cutting has some limitations:

- Slower cutting speed compared to laser or plasma cutting

- Abrasive consumption costs

- Water and noise management requirements

Applications of Waterjet Cutting Machines

Waterjet cutting is used in many industries for both simple and complex cutting work.

Aerospace & Defense

Waterjet cutting is employed to cut hard metals used in aircraft and defense equipment. It assists in creating correct parts without destroying the material.

Automotive & Manufacturing

Waterjet cutting is applied in the automotive industry when creating car parts and testing designs. It is applicable to small samples as well as large-scale production.

Architecture & Stone Industry

Waterjet cutting cuts stone, marble, and tiles that are utilized in buildings. It provides flowing lines and crispness to the design work.

Food Processing & Medical

Food and medical industries use waterjet cutting as it is clean and safe. It assists in cutting materials with no change needed.

Waterjet Cutting vs Other Cutting Technologies

Compared to laser and plasma cutting:

- Waterjet cutting offers superior precision with no thermal damage

- Laser cutting is faster for thin sheets

- Plasma cutting is cost-effective for thick metals

Safety & Maintenance Best Practices

Safe usage and frequent maintenance can ensure that the waterjet cutting machines can be used effectively and prolonged.

- Wear the right PPE and ensure proper operator training.

- Check nozzles and pumps regularly.

- Use coarse recycling and water purification systems.

Conclusion

Knowledge of the operation of a waterjet cutting machine assists manufacturers to make good decisions regarding precision cutting solutions. Ranging from ultra-high-pressure streams of water to CNC-controlled precision, waterjet cutting has widely become one of the most versatile technologies in the modern world.

As a company providing high performance and reliable solutions, WAMIT Waterjet has offered cutting edge waterjet cutting machines that are efficient, precise and in the long-term.

Frequently Asked Questions

Q. How thick can a waterjet cutting machine cut?

Waterjet machines can cut materials over 200 mm thick, depending on material type.

Q. Is waterjet cutting expensive?

Initial costs may be higher, but long-term savings come from reduced waste and minimal rework.

Q. Does waterjet cutting damage materials?

No. The cold-cutting process preserves material integrity.

Q. What industries benefit most from waterjet cutting?

Aerospace, automotive, stone, glass, food processing, and medical industries benefit significantly.