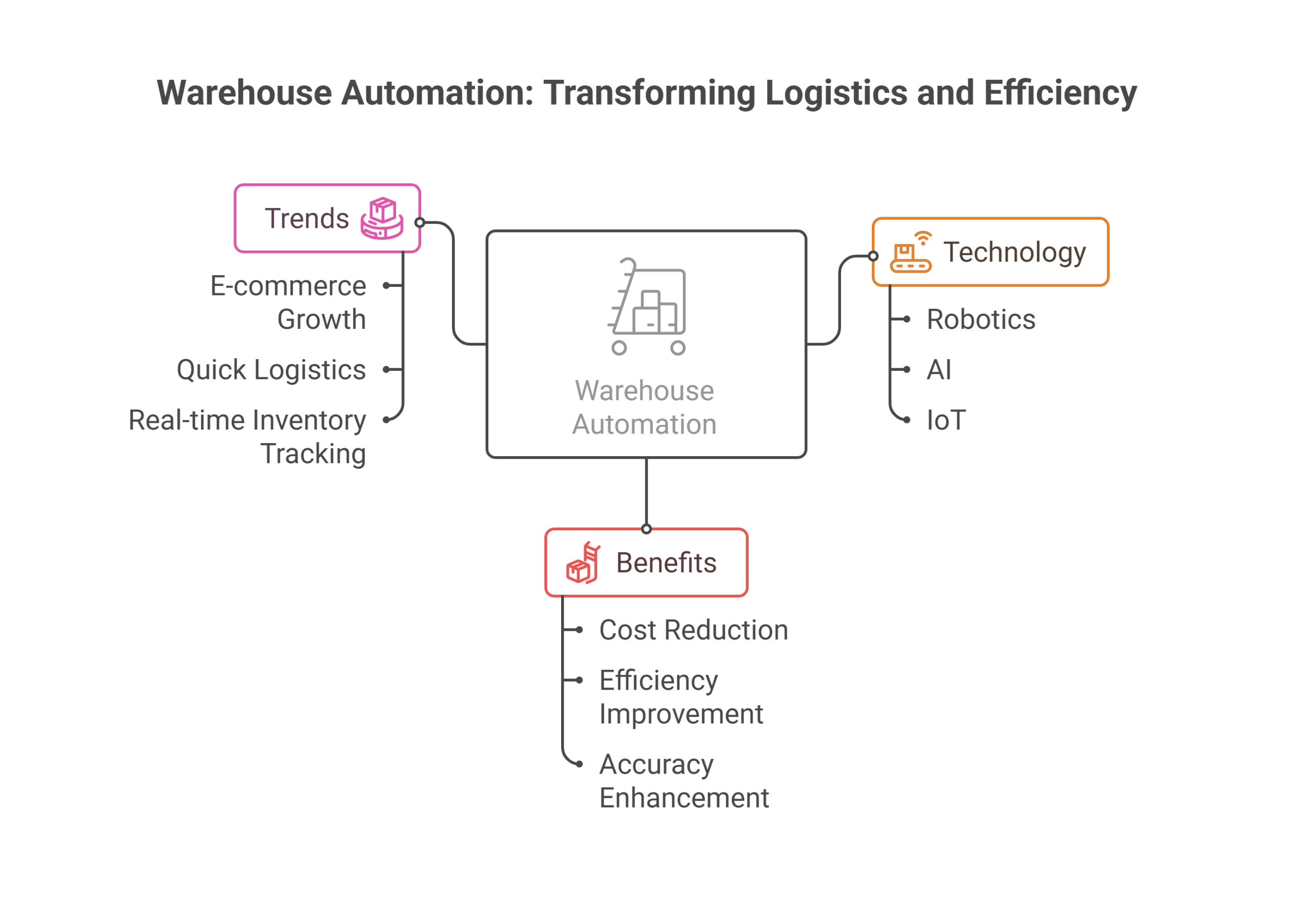

Warehouse automation involves the usage of technology to automate repetitive tasks within a warehouse. It deals with picking, restocking, packing, and shipping of orders. These inventory management tasks are labor intensive, and thus companies opt for automation, which helps them cut costs as well as reduce errors. Automation of warehouses also leads to efficiency in operations and customer satisfaction. It involves the usage of robotics, AI, ML, IoT and more to ease operations and inventory management.

Understanding latest trends in automation

There is a rise in developments in e-commerce and quick logistics. Customers expect quick and accurate deliveries, which are cost-effective, as well. Warehouses need to meet this demand by tracking inventory in real-time. This can be done with the help of automation, which facilitates seamless coordination within the warehouse and across the supply chain. This increases the demand for warehouse automation.

Warehouses need skilled labor to manage inventory and ensure proper delivery of goods on time. Manual labor is costly and inconsistent. This makes way for automation in warehouses, which reduces dependency on manual labor. Automation also provides consistency in operations. Developments in automation make it affordable for the warehouse owner. Developments in robotics and cloud computing make way for enhanced warehouse operations.

Understanding how automation is reshaping warehouse operations

Warehouse automation helps automate storage by using shuttles, cranes, and carousels to store and retrieve goods accurately, which helps optimize space and reduce human errors. Warehouse owners also make use of conveyors to shift products from one place to another. These conveyors are enabled with sensors to help with tracking of goods being shifted. The owners also make use of autonomous mobile robots that help with inventory handling, sorting, and transport. The arms of these robots are sometimes equipped with vision systems that help automate packing, sorting, and picking of goods. This helps reduce labor costs and helps improve accuracy. Sometimes, owners use digital platforms for processing orders and managing inventory. In addition, drones are also being used for managing inventory in the warehouse. This drives the growth of the warehouse automation sector.

Smart warehousing: usage of AI, IoT and robotics in warehousing

Usage of artificial intelligence in warehouses helps predict order volumes and allocate tasks in real-time. Usage of AI also helps optimize paths. Machine learning is also being integrated in automation systems in warehouses, which helps improve processes by analyzing historical data and identifying patterns. In addition, warehouses make use of devices that help communicate quickly. These are enabled with IoT sensors and provide real-time data on inventory levels, equipment status, and environmental conditions. Some warehouses also use collaborative robots, which are designed to work alongside humans. These robots help in packing, picking, and other human tasks to enhance efficiency and safety. These developments make way for smart, self-managing warehouses that can adapt to changes in real-time and operate with minimal human intervention. For instance, Honeywell International Inc. introduced smart warehouse execution software, in March 2025. This software works on a cloud-based platform.

Why is warehouse automation no longer optional?

Warehouse automation is reshaping the logistics landscape. It not only addresses the challenges of labor shortages and high operational costs but also opens new possibilities for speed, precision, and scalability. It is an important part of modern supply chain management. The integration of robotics, AI, IoT, and software systems has revolutionized the operations of warehouses and offers improved accuracy, efficiency, and scalability.

To get more insights into the latest advancements in warehouse automation, contact our industry specialists today! For any further queries, you can also chat with them directly.

Many businesses are opting for automation to sustain in the competitive environment. Warehouse automation is a sector which is driven by advancements in technology and reduction in labor cost. It also fosters efficiency and helps business save energy and overall cost. Therefore, warehouse automation is projected to gain traction in the upcoming years.