What is a Hall Effect Sensor

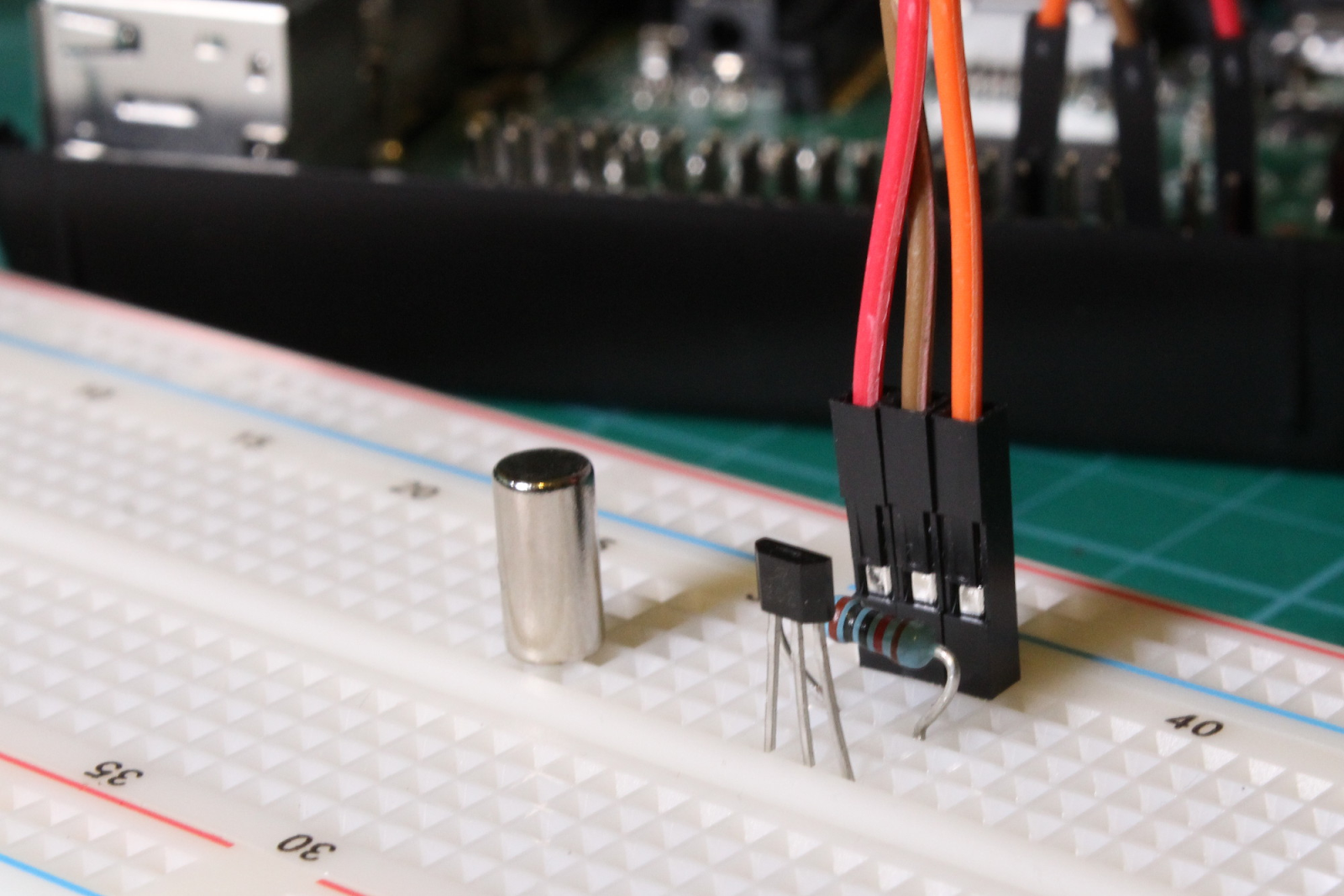

A device that detects a magnetic field and transforms it into an electrical signal is known as a Hall effect sensor. These sensors work on the basis of the Hall effect, which was discovered by Edwin Hall in 1879 when he found out that if a perpendicular magnetic field was applied to a conductor, a voltage difference set up would be created along the material: a voltage difference will be generated. Because of their extreme accuracy, dependability, and capacity for remote functioning, these sensors are frequently seen in industrial applications.

Compared to conventional mechanical or optical devices, Hall effect sensors represent a more simplistic and sturdy strategy to detect the position, speed, and current in a system without incurring any physical damage. Their functionality ability in harsh conditions makes them fit for different industries, which cuts across manufacturing, automotive, and automation. Integration of Hall effect sensors into systems results in increased efficiency, accuracy, and operational longevity of the industrial processes.

How Hall Effect Sensors Work

Hall effect sensors operate on the principle of change in magnetic field. They lack inbuilt and use a semiconductor chip, which when placed in a magnetic field produces voltage. The voltage is valid which directly describes anything that can be stored or conveyed in terms of information, while the electric signal is a processed item.

According to its use, it can be divided into two primary categories.

1. Analog Hall effect sensors: In this case, output is a voltage that is continuously flowing and is proportional to the strength of the magnetic field. It is useful in precision measurement, such as motor control and linear position sensing. It is also useful in precision measurements like motor control and linear position.

2. Digital Hall effect sensors: These sensors work with binary switches changing between two states as exposed to a certain level of magnetic field. They work the best for proximity and speed measuring. These are the most common sensors for proximity sensing and speed measuring.

Since there is no physical contact with the object being measured, Hall effect sensors provide excellent service life and maintenance free operation. This makes them ideal in the presence of dust, vibration and high or low temperature, which could be problematic for the conventional sensors.

Industrial Applications

Motor Speed and Position Control

Electric motors are extensively used for automation, conveyor, and robotic systems, making Hall effect sensors essential in almost every industry. These sensors aid in the detection and control of the motor speed by helping to trace the changes in the rotor’s magnetic field.

These sensors serve as vital feedback for the commutation of brushless DC (BLDC) motors to ensure the smooth and best efficiency running of the motor.

Operating efficiency and product quality in industries like semiconductor fabrication, automotive production ,and any precision engineering activities relies heavily on accurate motor control for achieving productivity. Motor control becomes a precise science in the following industries:

Proximity Sensing in Automation

Close range electronic perception such as magnet activated Hall effect sensors, are a vital part of automation machinery. Security systems, automated assembly lines, industrial robotics all benefit from their ability to identify the presence or absence of magnetic objects.

In such systems, these sensors facilitate in enabling arms to execute precise and repeatable operations by clearly identifying the location of the moving parts in robotic arms. These units also make it easier for production systems with conveyor belts to identify when objects are going through different phases in the production processes which increases the level at which workflows are automated. Using a Hall effect sensor allows mechanical contact hence no contact means no prolonged wear hence reduced downtimes and cost from maintenance.

Current Sensing in Power Systems

Hall Sensor Effect proves essential, alongside automation temperature measurement, breakdown detection and overload protection in managing and monitoring power in extension. Moreover, these sensors enhance security because they do not require contact with the conductor, which means less energy is wasted and more safeguarded.

These sensors are applied in power supply units, battery management systems, and systems dealing with renewable electric energy. Sensors aid in automatic monitoring and control device to balance consumption, detect overload and therefore improve efficiency of energy usage. Current sensing in automation applied to electric vehicles and industrial systems ease the distribution of power to systems b which reduces system failure and improves electric energy efficiency.

Fluid Flow Measurement

Flow meters also utilize Hall effect sensors to track the motion of fluids. In several industries like pharmaceuticals, water treatment, and chemical processing, accuracy in flow measurement is critical for precise process control.

Hall effect sensors transform flow rate into an electric signal by sensing the rotation of a magnetic turbine within a pipe. The signal allows real-time monitoring, which enables industries to control precise movement of fluids for quality and efficiency in production.

Please check this page for a varied range of industrial proximity sensors: https://www.omchsmps.com/es/path/proximity-switch/

Benefits of Hall Effect Sensors

Hall effect sensors have many advantages compared to traditional optical and mechanical sensors.

– Non-contact operation – No moving parts means no mechanical wear which translated to lesser maintenance costs.

– High durability – Can provide reliable service in extremely harsh conditions of dust, moisture, and extreme temperatures.

– Fast response time – Enables accurate control and monitoring in real time.

– Low power consumption – Useful in systems powered by batteries and applied in energy saving devices.

– High accuracy and repeatability – Provides dependable performance on industrial applications.

Due to all the benefits provided, Hall effect sensors are a cornerstone for industrial automation and electronic systems.

These sensors can be used to enhance performance and reliability while simultaneously improving efficiency and reducing operational costs.

Choosing the Right Hall Effect Sensor

In any given industrial setting, businesses need to put into consideration certain parameters in choosing a Hall effect sensor:

– Operational requirements – Figure out the purpose of the intended use so that a decision can be made on whether an analog or digital sensor is required.

– Power supply and voltage – The sensor should be able to function within the boundaries set by the current electrical systems.

– Magnetic and sensitivity range – The sensor chosen should have the ability to detect magnetic fields at the appropriate threshold.

– Sensor Specifications – Environmental factors like temperature, humidity, and other contaminants should be considered.

– Sensor Structure – Check that the sensor can be installed in the configuration or structure without too much hassle.

A business looking for optimal performance alongside long term reliability in a given industrial application should look to choose the correct Hall effect sensor. There are numerous options available and businesses can find varying solutions depending on their specific automation and sensing requirements.

Motion control, proximity sensing, current measurement, and fluid flow monitoring are some of the areas where Hall effect sensors detect with great accuracy and reliability, and this places them at the core of industrial applications. Their ability to operate without contact makes them suitable for the automation and manufacturing industries.

As sensor technology makes new strides, they are becoming much more adaptable as well as efficient, and Hall effect sensors are leading the charge in this matter.

Since different industries are embracing smart automation tools, the importance of these sensors will continue to grow in enhancing accuracy, efficiency, and longevity within a system. Adjusting to modern advancements will be made easier with these tools. Companies wanting to buy high quality Hall effect sensors will find a wide variety of industrial sensors with OMCH. The right sensor technology allows companies to streamline processes, maximize productivity, and succeed in industrial automation for a long time.