Consistency in overall performance from the product, aesthetic design, and durability serves as a primary foundation for success in the furniture hardware industry. The longevity and quality of hardware components are seeing drastic enhancements with anodizing, a high-level surface treatment that is seemingly revolutionary in its approach. Incorporating new age anodizing techniques are able to make advanced furniture hardware components that not only look phenomenal, but also avoid corrosion and increase performance. This details how new age anodizing techniques are shifting the furniture hardware industries landscape towards better aesthetic and functionality.

What Exactly Is Anodizing

Anodizing is a process where aluminum surfaces go through electrochemical application to enhance the thickness of its oxygen layer, and is then altered in order for it to be resistant towards wear, rusting, and corrosive elements all while enhancing the aesthetic features of the metal. This process is essential when creating items that are at risk of being damaged by moisture and chemicals because it aids in protecting them. Anodized surfaces tend to be more appealing and have a longer lifespan. Metals are more prone to damage from surrounding conditions and anodized components are highly beneficial due to being coated with a protection layer. A protective layer such as plastic or paint cannot be used because they tend to wear off easily and pose a threat to the surface underneath. Use of Gives layers of anodized coatings the ability to accept prints of designs, making them more attractive. They deepen the overall aesthetic appeal, in addition to having a long lasting lifespan and most importantly, they actively oppose rusting, and other forms of damage.

The process improves the strength, durability, and appearance of the product, ensuring that both the manufacturers and the end users are satisfied. Investing in anodizing technology can help furniture hardware manufacturers deliver quality products that last a long time.

The Role of Anodizing in Enhancing Durability

One of the most notable benefits of anodizing is how it improves the durability of metal products. Anodizing is when a protective layer is formed on the surface of the metal that is harder than the metal. This added hardness improves the resistance to scratches, wear, and corrosion. Anodized products are great for use in places where there is moisture, temperature changes, and frequent handling.

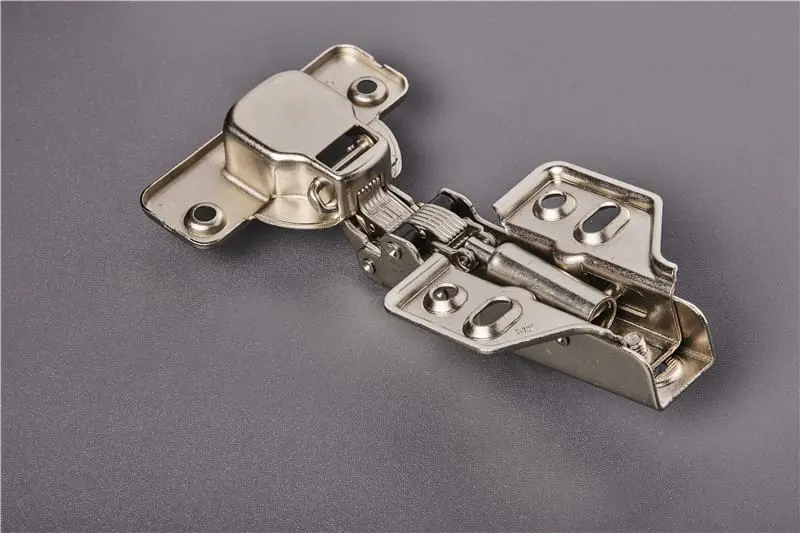

As an example, companies producing hinges, drawer pulls, and other components can take advantage of anodizing in order to extend the durability of their products. Anodized hardware is far more corrosion resistant which is particularly useful for furniture placed in kitchens and bathrooms. This added durability means less replacements and repairs, resulting in cost savings.

Moreover, anodizing improves the quality of the metal surface, making it easier to maintain and clean.

That is important for a company that wants to provide its consumers with quality products that require minimal care, especially in fields… where functionality and aesthetic appeal is important.

Aesthetic Advantages of Anodizing

Even though anodizing is best known for increasing the strength of metal parts, it also provides crucial aesthetic benefits. The anodizing process has the ability to produce various colors and finishes, which enables furniture hardware manufacturers to design and customize different products.

The range of available colors, from muted silver and bronze hues to vivid reds, blues, and greens, makes the product stand out and appeal to designers, architects, and furniture manufacturers. Anodized furniture hardware can be thoroughly integrated into various design styles, whether it is modern minimalism or traditional rustic.

Anodizing: A Sustainable Solution

Anodizing in addition to color allows for alterations in textures and finishes that include matte, satin, and high gloss. These anodized finishes can make the hardware components more ideal to potential buyers. For example, in the US, the upper-end manufacturers of kitchen and office furniture can easily use anodized derivatives in their products for the best combination of functionality and aesthetic appeal.

In the context of eco-awareness in modern days, B2B companies in the furniture hardware sector focus heavily on good environmental practices. Anodizing is a process that is sustainable and consumes less chemicals. It also yields less waste compared to other metal surface treatments like painting or plating. Because of its low impact to the environment, it is perfect for companies who want to lessen their carbon footprint without compromising product quality.

Anodizing elongates the lifespan of pieces, lessening the need for excess replacements, thus promoting a more sustainable form of resource consumption. This decreases the overall carbon footprint that comes from the manufacturing processes since waste is reduced and material reuse is encouraged. Although companies face challenges to adopt these eco-friendly practices, those willing to embrace such transformations will reap the benefits of meeting standards as well as pleasing customers through appropriate application of anodizing technology.

Also, after the life cycle of anodized products, they can be reclaimed 100%. This is consistent with the projected increase of circular manufacturing and contribution to reducing resource consumption issues in the furniture hardware sector.

For multinational companies that produce furniture hardware, implementing modern technology in anodizing surfaces will help companies remain relevant in an ever changing market.

Benefits for B2B Furniture Hardware Manufacturers

Firms opt for иonizing works to their advantage because in today’s world of furniture hardware production where the demand is for high quality and good looking, as well as eco-friendly accessories increasing by the moment, demand tends to be constant.

These attributes include the following ones:

Enhanced Durability:

Kitchen and bathroom pieces of furniture are getting high use so anodized components have particular add-ons for these environments to fit into to ensure there are no scratches, wear or corrosion on the pieces.

Customization Options:

Various design work has particular specifications, especially for newer sleek modern styles, and anodizing offers a wide variety of colors and finishes, thus ensuring alignment with design preferences.

Sustainability:

Because the processes of anodized coatings require fewer harmful chemicals, there are significantly reduced amounts of waste. Besides the above mentioned, the coating of anodized aluminum is highly endorsed because of its eco-friendliness by the end of the product’s life.

Long-Term Cost Savings:

Reducing the amount of repairs and replacements needed leads to considerable savings in anodized hardware when it comes to pieces of furniture that have many working components.

Improved Brand Reputation:

The customer’s trust can significantly improve if anodized parts of the pieces of furniture are guaranteed to be non-removable, reliable, and sustainable.

By using anodizing processes, hardware manufacturers in the USA will also have a decisive advantage over their competitors, and will be able to use these tools on the global market. Further, when these companies consider developing new products aimed at those who look for high durability, design as well as being eco-responsible, using anodizing technologies will allow these companies to gain new customers.

Boosting the demand for high performance eco friendly types of products is tough, but not impossible.

With the introduction of the modern anodizing processes to the furniture hardware industry, there is great appeal to furthering enhanced sustainability, durability, while making them aesthetically pleasing.

For the producers of furniture hardware, it is quite imperative to adopt anodizing technology since it improves the quality and aesthetics of their products as well as meets the need for eco-friendly solutions. Manufacturers who offer customization and exceptional product durability towards their clients will, in return, have a more favorable position in the market that is becoming more and more competitive.

For the furniture hardware manufacturers in the USA and throughout the world, adopting anodizing stands to be highly beneficial in respect to quality of the products, savings in costs as well as the perception of brand equity. Indeed, the fast-changing environment would mean that anodizing will undoubtedly become the centerpiece of modern advancements in the furniture hardware industry.