Fiberglass moulded gratings have transformed the industrial flooring sector as they are far more durable, corrosion resistant, and lighter than steel or wood. In India, the requirements of such gratings have reached a new high not only in the chemical industry but also in the marine, oil and gas, and infrastructure sectors.

These gratings are movement icons of the Indian market that can withstand highly aggressive environments with very little intervention, requiring just simple cleaning. The article discusses the top Fiberglass Moulded Gratings Manufacturers in India who are featured with their most sophisticated products and the impact on the market. Among them, Fiber Tech Composite Pvt Ltd., located in Rajkot, is the leading provider of quality and customization.

Why Fiberglass Moulded Gratings Are a Big Deal

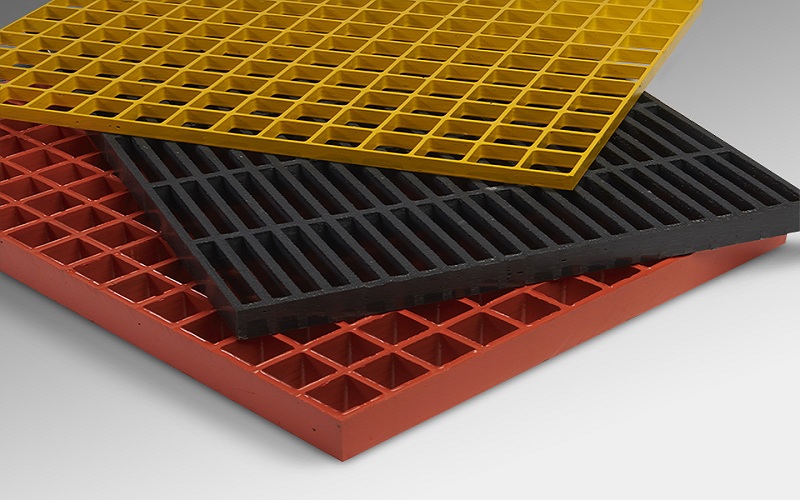

These gratings are no ordinary flooring. They’re made by layering fiberglass rovings with thermosetting resins, then curing them into panels with neat square or rectangular meshes. Think walkways, platforms, stair treads, or trench covers that don’t flinch in the face of harsh conditions. They shrug off rust, weigh next to nothing compared to steel, and come with grippy surfaces to keep workers steady. That’s why they’re a top pick for industries chasing durability and safety.

What Makes Them Stand Out

These gratings resist acids, alkalis, and saltwater, lasting years where steel would crumble. They’re so light they make installation a breeze and don’t stress out supporting structures. No electrical conductivity means they’re safe around power lines, and their gritty tops cut down on slips. Best part? You can tweak their size, color, or resin type to match any job, giving you flexibility that’s hard to beat.

Where They Show Up

Chemical plants use them to handle corrosive spills without breaking a sweat. Marine setups like docks lean on them to fight off saltwater damage. Food processing plants love their clean, non-porous surfaces for staying hygienic. Even bridges and walkways in big infrastructure projects rely on their strength without the bulk, which is why they’re popping up all over India’s growing industrial scene.

The Best Fiberglass Moulded Gratings Manufacturers in India

India’s got a killer lineup of manufacturers pumping out top-notch fiberglass moulded gratings. Here’s a look at the heavy hitters, with the scoop on their skills, breakthroughs, and real-world wins, all backed by hard facts.

Fiber Tech Composite Pvt Ltd.

Hailing from Rajkot, Gujarat, Fiber Tech Composite Pvt Ltd. is a big name in composites. They’ve got ISO 9001:2008 certification, meaning their gratings are built to take on the worst environments, with a beefy resin-to-glass mix for extra toughness. They’re all about custom jobs, letting you pick resins, mesh styles, and colors for gigs in chemicals, marine, or power plants. Their stuff ships to over 26 countries, showing the world trusts their quality. They’re also big on keeping things green, with low-maintenance products that save cash long-term.

Innovations:

- Resins fine-tuned to shrug off UV rays and chemicals, so they last ages.

- Modular panels that click together fast, even in weird layouts.

- Eco-friendly production that keeps waste low.

Case Study: A fertilizer plant in Gujarat slapped Fiber Tech’s gratings into a zone hammered by ammonia and salty air. Seven years in, they’re still going strong, saving 45% on maintenance compared to steel.

Aeron Composite Pvt. Ltd.

Over in Ahmedabad, Gujarat, Aeron Composite cranks out wallet-friendly FRP solutions. Their gratings, packing 35% glass and polyester resin, spread weight evenly. With UV protection and chemical resistance, they’re perfect for pharmaceuticals, pulp mills, and offshore rigs. They’re champs at customizing sizes and load limits to nail specific jobs, which keeps them in demand.

Innovations:

- Lightweight gratings that don’t bog down elevated walkways.

- Silica grit surfaces that stay grippy for years.

- Fast prototyping to whip up custom designs.

Case Study: A Hyderabad pharma plant used Aeron’s gratings for cleanroom floors. Their non-conductive, hygienic setup dropped safety mishaps by 25% and made passing inspections a cakewalk.

Fibrograts Pvt. Ltd.

Out of Indore, Madhya Pradesh, Fibrograts has been at it for over 30 years, mastering FRP. Their gratings are bulletproof against corrosion and can handle heavy loads, serving clients in 10 countries across Africa, Europe, and Asia-Pacific. They cover everything from design to installation, keeping things tight. They’re also eco-conscious, using recyclable resins and energy-saving methods.

Innovations:

- UV-resistant resins that hold up outdoors forever.

- Heavy-duty gratings that laugh at forklift traffic.

- Designs tweaked based on what clients say.

Case Study: A Maharashtra wastewater plant put in Fibrograts’ gratings, which stood up to nasty effluents for 15 years longer than metal would’ve.

Amrock

Also in Ahmedabad, Gujarat, Amrock sends FRP gratings to places like Saudi Arabia, Qatar, and South Africa. Their bi-directional strength comes from layering fiberglass with polyester resin, cured just right. You can get them in custom colors and mesh patterns, and their pultruded gratings tackle high loads.

Innovations:

- I-bar pultruded gratings for big spans.

- Fire-proof resins that meet strict safety codes.

- Clean cuts to keep waste low on-site.

Case Study: Amrock’s gratings went into a Mumbai offshore oil platform, where their light weight and rust resistance cut setup time by 20% and slashed maintenance costs over a decade.

Ventura Fibre Tech

Down in Chennai, Ventura Fibre Tech builds chemically resistant gratings for heavy-duty spots like forklift zones. Their 35% glass and polyester resin gratings match steel’s deflection limits. They cut panels to exact specs, keeping waste down.

Innovations:

- Silica grit surfaces that don’t lose grip.

- Five resin options for different environments.

- Cable tray systems that pair with gratings for full setups.

Case Study: A Tamil Nadu desalination plant used Ventura’s gratings, which held firm against saltwater for 18 years without needing a swap.

Factors Driving the Growth of Fiberglass Moulded Gratings Manufacturers in India

India’s fiberglass moulded gratings market is on fire, thanks to some big trends.

Industry Growth

India’s building smart cities and industrial hubs, needing materials that last without constant fixes. Fiberglass gratings are perfect for bridges, platforms, and factory floors, with quick installs and long lives.

Safety Demands

Tough rules in oil and gas, chemicals, and power call for non-conductive, non-slip flooring. These gratings check those boxes, keeping workers safe and compliance costs down.

Sustainability Trends

With the world pushing for sustainability, manufacturers like Fiber Tech Composite Pvt Ltd. are using eco-friendly resins and cutting waste. The gratings’ recyclability and durability fit right into green goals.

Export Surge

India’s cheap manufacturing and skilled workers make it a global FRP hotspot. Companies like Fibrograts and Aeron are hitting markets in Asia, the Middle East, and Africa, raking in export bucks.

How to Choose the Right Fiberglass Moulded Gratings Manufacturer

Choosing a solid manufacturer can make or break a project. Here’s what to keep in mind, straight from industry know-how.

Quality Certifications

Select manufacturers having ISO 9001 or similar. Fiber Tech’s ISO 9001:2008 means you’re getting reliable quality.

Customization Capabilities

Jobs often need specific sizes, load limits, or resins. Aeron and Fibrograts are pros at tailoring to fit your needs.

Industry Experience

Old hands like Fibrograts, with 30 years under their belt, bring tried-and-true reliability and deep industry smarts.

After-Sale Support

Top players offer setup tips and maintenance advice. Fiber Tech’s quick support through calls, emails, or site visits is a benchmark.

Cost vs. Value

Fiberglass gratings might cost more upfront than steel, but they save big on maintenance and replacements. Look at the full cost picture.

Challenges Facing the Industry

The industry’s growing, but it’s got some bumps to smooth out.

Raw Material Price Volatility

Resin and fiberglass costs can jump around. Manufacturers are locking in smart supply deals and checking out alternative materials.

Competition from Traditional Materials

Some folks still cling to steel or concrete. Showing the long-term perks of fiberglass is the way to change minds.

Skilled Labor Shortages

Precision work needs skilled hands. Companies are training up their teams to keep quality high and ideas fresh.

Future Trends in Fiberglass Moulded Gratings Manufacturing

The industry’s not standing still, with new tech and trends pushing it forward.

Advanced Resin Systems

New vinyl ester and phenolic resins are upping fire and chemical resistance, making them fit for risky spots like power plants.

Automation in Production

Automated moulding and curing, like what Tribeni Fiber’s doing, keeps quality tight and speeds up delivery for big jobs.

High-Tech Gratings

Early tests with sensor-embedded gratings could let industries like oil and gas track loads live, boosting safety.

Greener Production

Eco-friendly resins and energy-saving methods are catching on, keeping up with global green rules.

Comparative Analysis of Top Manufacturers

Here’s a snapshot of the top manufacturers to help pick the right one:

| Manufacturer | Location | Strengths | Export Markets | Customization | Sustainability |

| Fiber Tech Composite | Rajkot, Gujarat | ISO-certified, extremely durable | 26+ countries | Lots | Big focus |

| Aeron Composite | Ahmedabad, Gujarat | Lightweight, UV-proof | Global | Lots | Decent |

| Fibrograts | Indore, MP | 30+ years, full-service | 10 countries | Lots | Big focus |

| Amrock | Ahmedabad, Gujarat | Export-driven, strong build | Middle East, Africa | Some | Decent |

| Ventura Fibre Tech | Chennai, TN | Chemical-proof, modular | Mostly domestic | Some | Decent |

Practical Applications and Installation Tips

Fiberglass moulded gratings are super versatile, but getting them set up right is key.

Common Applications

- Walkways and Platforms: Light weight means less strain on structures.

- Stair Treads: Grippy surfaces keep high-traffic areas safe.

- Trench Covers: Non-conductive for electrical or drainage setups.

- Tree Grates: Let water pass while guarding roots.

Installation Best Practices

- Prep: Make sure supports are flat and clean for even weight.

- Fixing: Use stainless steel M-clips or T-clips, locking panels at four points.

- Cutting: Diamond-tipped saws give clean edges, less waste.

- Load Check: Match load ratings to the job to avoid sagging.

Why India Leads in Fiberglass Moulded Gratings Manufacturing

India’s got the upper hand in fiberglass moulded gratings because:

- Low Costs: Cheaper labor and materials than Western markets.

- Skilled Crews: More folks trained in composites.

- Prime Location: Near shipping routes for easy exports to Asia, Middle East, and Africa.

- Government Push: Make in India’s boosting manufacturing.

Global Impact and Export Potential

Indian manufacturers are making moves worldwide. Fiber Tech hits 26 countries, and Amrock’s big in the Middle East. The global FRP grating market, worth USD 1.2 billion in 2023, is set to grow 5.8% a year through 2030, with India grabbing a chunky share.

Maintenance and Longevity Best Practices

To make gratings last:

- Clean Often: Mild soaps keep surfaces grippy.

- Check Regularly: Spot cracks or wear in heavy-use zones.

- Sun Protection: UV coatings for sunny spots.

- Load Limits: Stick to rated weights to avoid damage.

Addressing Common Misconceptions

Some folks shy away from fiberglass gratings because of wrong ideas:

- Myth: They’re weaker than steel. Fact: No, they can handle the same loads if designed right.

- Myth: They fade fast outside. Fact: UV-protected resins keep them solid for decades.

- Myth: Hard to install. Fact: Light, modular designs make it simple.

Final Thoughts

The FRP Moulded Gratings Manufacturers in India, led by companies like Fiber Tech Composite Pvt Ltd., Aeron Composite, Fibrograts, Amrock, and Ventura Fibre Tech, are breaking records in the global market by quality, innovation, and sustainability. Their excellent capability in providing customized, corrosion-resistant, and affordable products has made India a center of FRP goods in the world. As industries focus on safety, durability, and eco-friendliness, these manufacturers are capable of fulfilling the changing requirements, not only local, but also global growth. For businesses that are looking for reliable grating solutions, joining with these industry leaders will definitely guarantee the performance and value that will not fade away over time.