Why Seat Material Matters?

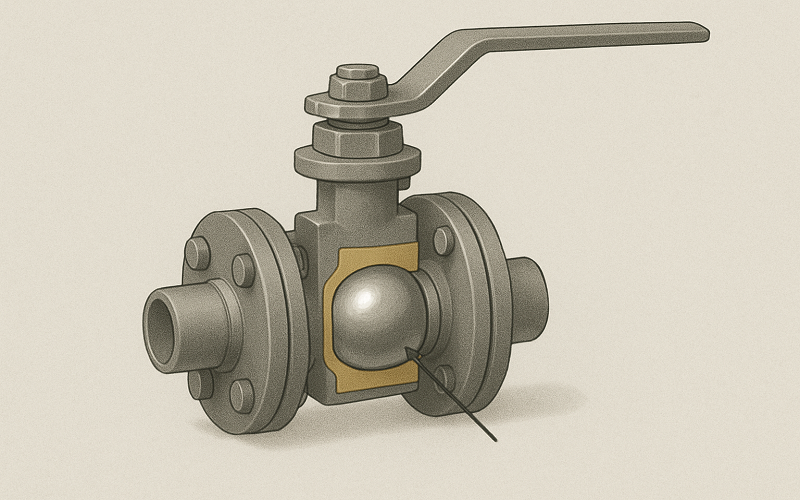

Stainless steel ball valves are renowned for their durability, corrosion resistance and ability to withstand aggressive operating environments. But the stainless steel body is not all that influences the valve. The control of the high portability and the reliable sealing action path between ball and valve body that is formed by the seat material machined to create a sealing surface for closing which has an essential role in allowing smooth operation from opening to closure are closely related to performance maintenance. Without the correct supplies, issues like leaks, pressure decline and excessive wear can damage not only your system but also surrounding valves. Selecting the right stainless steel ball valve manufacturer materials contributes to safety, efficiency and durability for the valves especially when they are experiencing action from steam, chemicals, hydrocarbons, abrasive slurries or high temperature fluids.

PTFE (Teflon) for industrial usage

In general, PTFE is the most common exhibition seat material used because of its chemical resistance and relatively low friction. It works great with water, mild chemicals, and food grade media. It smooth design makes the ball easy to turn while maintaining superior seal performance over time. PTFE is good for most states of climate and weather It can be used at temperatures ranging from -180°C to 260°C long term, uses even under the condition of high temperature149 °C furthermore with an aging temperature of 200 °C and a melting point of 327/342°C PTFE is not resistant to solvents.

Higher Temperature and Pressure Resistant

When a higher strength and temperature resistant material is desired than standard PTFE, filled PTFE is recommended. The finest type of PTFE offers enhanced properties for the most demanding applications. Following basic types of materials are available for stock shapes, other sizes and customized thickness or diameters might be available from polymer producer. RPTFE is a modified form of PTFE with fillers such as carbon or glass which render it more heat, pressure and wear resistant. This makes it applicable for steam lines and handling chemicals after where the service requires stability at higher temperatures. Owing to these versatile characteristics, a Stainless steel ball valve manufacturer often recommends PTFE seats for general-purpose industrial applications where reliable sealing and easy operation are required.

PEEK for Extreme Industrial Conditions

PEEK is one of the highest level of seat materials for severe applications. Able to withstand high pressure, vibration and temperature; PEEK is a robust alternative to traditional O-rings and brass seats for tough applications PEEK’s Ample Strength, Thermal Resistance and Compatibility with Extreme Industrial, Turbine Operations & Aggressive Chemicals Make It Perfect For Oil & Gas, Petrochem Plants in which Sealing Failure is not option. Even with fluctuations in temperature, system pressure and so on, PEEK still has excellent structural properties that produce sealing accuracy.

Polyoxymethylene (POM) for Mechanical Applications

Some applications, such as actuation of automated systems and hydraulic systems, demand high mechanical rigidity to cope with multiple actions. Delrin has great tensile and dimensional stability which translates into impeccable performance even during fast and continuous valve cycling. But it is more appropriate for non-corrosive and general temperature uses not when subject to high temperature or strong acid.

Metal Seats for Severe Environments

In the harshest industrial environments, high temperature, high pressure and containing abrasive or erosive particles in the flow media, requires metal seats. Stainless steel ball valves have metal that may be hard coated to provide abrasion resistance and increase the ability to perform in thermal shock. These high quality valves are essential in mining, refineries, high temperature gas and steam lines, superheated steam houses and power generation plants. Whilst most people regard metal seats as a more expensive option that may need higher operating torque, they can outlast and outperform in tough service conditions, thus offering a good long term value comparison.

Selecting the Right Seat Material for Your Application

Choosing the seat material is a delicate game that requires to take best into account your working condition. Each application requires its own compromise between resistance to temperature, pressure, chemical compatibility and mechanical strength. An application which involves clean fluids in food processing or pharmaceutical industries calling for hygienic and non-friction sealing with PTFE. Using RPTFE or PEEK to increase stability for a plant with high pressure steam cycles. Oil and gas & refineries Salient feature PEEK/Metal seats need to be used for oil and gas and refinery applications, which can resist thermal stress as well as corrosive hydrocarbons. Operations designed to handle abrasive materials, liquid product slurries or other aggressive particulates require metal seated valves to resist erosion and failure. Although cost is part of the equation, if you start with the right seat, in most cases maintenance shutdowns are reduced and valve life is extended – thus reducing total operating costs.

Conclusion

Seat material is not an accessory, it’s a performance valve component of any stainless steel ball valve. PTFE excellent for general applications, Reinforced PTFE the strength and heat tolerance rises with this option, PEEK for optimum sealing under world’s industrial demands, Delrin reliability while faced with repetitive mechanical stress or loading, Metal Seats Hard facing in the toughest working environments. When seat material is properly selected for application, industry achieves the highest integrity seal, increased safety levels, increased efficiency and lower down time and valve life.