Steel shapes our world in ways you might not notice every day. Billions of tons of it go into buildings, cars, and machines each year. Mild steel plates stand out as the workhorse material that keeps it all together, thanks to their simple build and tough nature.

Mild steel is a type of low-carbon steel with less than 0.3% carbon by weight. It tops the list as the go-to steel worldwide because you get solid performance without breaking the bank. In this piece, you’ll dig into its makeup, key traits, and where it shines in real jobs. We’ll cover the elements that make it tick, how it bends and holds up, and the industries that can’t get enough of it.

Decoding the Composition of Mild Steel Plates

Mild steel plates get their name from the low carbon levels that keep them soft and easy to shape. This mix sets them apart from tougher steels and makes them perfect for everyday builds. Let’s break down what goes into these plates.

Chemical Makeup and Carbon Content Thresholds

At its core, mild steel is mostly iron, around 99%. Carbon sits at the heart, usually under 0.25% to 0.30%, depending on the grade. This low amount stops the steel from getting too hard, so it stays flexible.

You also find manganese up to 1.6%, which boosts strength without adding weight. Silicon hovers around 0.5% to help with deoxidation during melting. Traces of phosphorus and sulfur, below 0.05% each, keep things clean but can make the steel brittle if they climb too high.

Carbon acts like the boss of hardness in steel. Too much, and your plate turns rigid and hard to weld. In mild steel, that low carbon keeps it user-friendly. For example, ASTM A36 grade caps carbon at 0.26%, ideal for basic structural work.

Common Alloying Elements and Their Function

Manganese steps in to improve toughness and wear resistance. It helps the steel fight dents and cracks under stress. Without it, mild steel might buckle too soon in heavy use.

Silicon aids in removing oxygen from the melt, leading to a purer product. Phosphorus adds a bit of strength but can make the metal cold and short. Sulfur does the same, so mills keep both low to ensure smooth welds.

Compare this to medium-carbon steel, which packs 0.3% to 0.6% carbon for more strength but less bend. High-carbon types go even further, over 0.6%, and suit tools, not plates. Mild steel skips those extras, focusing on ease over extreme power.

Key International Standards Designations (e.g., A36, S275)

Standards like ASTM A36 from the U.S. set rules for mild steel plates in building. This grade promises at least 36,000 psi yield strength and fits general construction. In Europe, EN 10025 covers S275, with similar low carbon and manganese for structural beams.

These labels guarantee quality from mill to site. A36 plates often show up in U.S. bridges and frames, while S275 handles EU projects. Check the spec sheet to match your needs, like thickness or impact tests.

Mills test each batch to meet these marks. This keeps plates reliable, whether you’re welding a frame or bolting a base. Standards bridge the gap between raw material and finished job.

Critical Mechanical and Physical Properties

What makes mild steel plates a smart pick? It’s the mix of strength and give that lets you form them without headaches. These traits shine in tests and on the shop floor.

Strength, Hardness, and Ductility Balance

Tensile strength in mild steel plates runs from 400 to 550 MPa, meaning they pull apart only under big force. Yield strength starts at 250 MPa for grades like A36, so they hold shape under load. Hardness stays low, around 120-150 Brinell, which keeps them from scratching easy.

Ductility lets these plates stretch up to 20-30% before breaking. Think of it like taffy—it deforms instead of snapping. This quality suits bending or stamping without heat, saving time in fab shops.

You can form complex parts, like brackets or guards, right from the plate. Low hardness means tools last longer too. Balance keeps mild steel versatile for loads that aren’t extreme.

Weldability: The Fabricator’s Primary Concern

Mild steel welds like a dream because low carbon avoids brittle zones. You join plates with common methods like MIG or stick, using basic filler rods. No need for fancy preheats, unlike high-carbon steels that crack on cooling.

The American Welding Society notes mild steel needs simple prep, like clean edges. Risks stay low, so joints hold strong. This trait cuts costs on big projects, where welds cover miles.

Ever wonder why bridges last decades? Solid welds from mild steel plates play a big role. Pick the right electrode, and your fab turns out tough and quick.

Corrosion Resistance and Durability

Bare mild steel rusts in wet air, losing thickness over time. Iron reacts with oxygen and water to form flakes that weaken it. Expect 0.1 mm loss per year outdoors without protection.

Coatings change the game. Galvanizing adds zinc for 20-50 years of life in mild weather. Paint seals it too, often doubling indoor use.

Data from ASTM shows galvanized plates outlast bare ones by five times in salt spray tests. For outdoor frames, always spec a finish. Durability comes from smart add-ons, not the steel alone.

Manufacturing Processes for Mild Steel Plates

Turning molten steel into flat plates takes skill and heat. Mills shape it to exact sizes for your blueprint. These steps ensure plates arrive ready to cut and weld.

Hot Rolling vs. Cold Rolling Techniques

Hot rolling heats steel to 900-1200°C, then squeezes it between rollers. This makes thick plates, from 3mm to 200mm, with a scaly surface. It’s fast for bulk runs, like ship hulls.

Cold rolling follows, at room temp, for thinner sheets under 3mm. It smooths the finish and tightens tolerances to 0.1mm. You get precision for panels or frames.

Hot suits pressure vessels needing girth; cold fits enclosures wanting shine. Pick based on your thickness and look needs.

Dimensional Tolerances and Thickness Capabilities

Plates come in widths up to 3 meters and lengths to 12 meters. Thickness spans 0.5mm for sheets to 150mm for slabs. Hot-rolled tolerances allow 0.5% width variation; cold hits 0.2%.

Normalized plates, heat-treated, stay flat better than as-rolled. Use normalized for tight fits in machinery bases. Check ISO 9445 for euro specs on edges and flatness.

Spec thin for light loads, heavy for bridges. Mills cut to custom sizes, so order smart.

Surface Finishes and Quality Control

Mill scale from hot rolling looks rough and rusty. Descaling with acid or shots blasts it clean for painting. Pickled plates gleam, ready for galvanizing.

Quality checks include ultrasound for cracks and tensile tests for strength. ISO 9001 certs prove consistency. Finishes matter—smooth ones bond coatings better.

Post-process to match your end use. A clean surface means longer life in harsh spots.

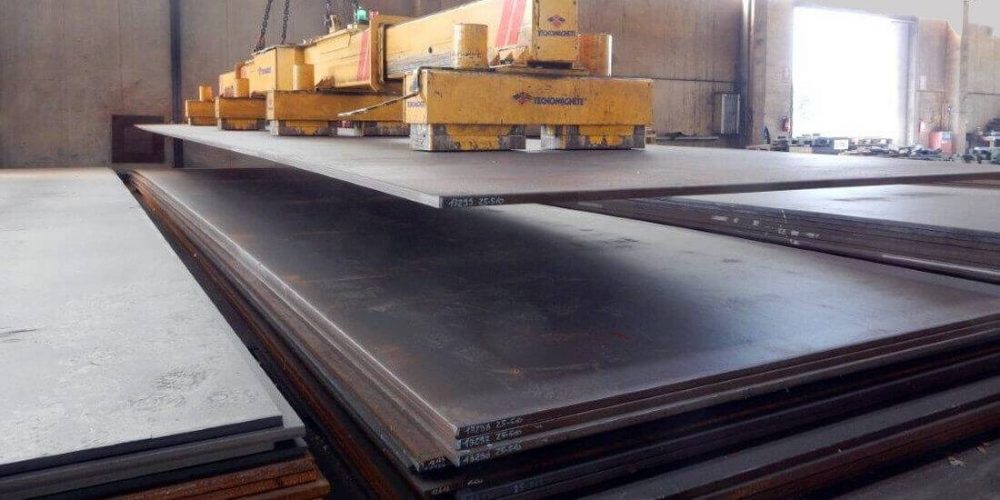

Versatile Applications of Mild Steel Plates Across Industries

Mild steel plates pop up everywhere because they weld easy and cost little. Their strength handles daily stress without fuss. Let’s see how they fit key fields.

Structural and Civil Engineering Applications

In buildings, plates form beams and columns that support floors. You see them in bridge decks, holding traffic loads for years. Cost keeps projects on budget.

Framing for warehouses uses welded plates for open spans. They resist quakes thanks to ductility. Real example: The skeleton of a new mall relies on A36 plates for stability.

Weld and bolt them for quick assembly. Engineers love the balance of safe and cheap.

Manufacturing and Heavy Machinery Fabrication

Machine bases start as thick plates, milled flat for vibration control. Chassis for cranes weld from them, bearing tons. Supports under pressure stay put under force.

Non-critical tanks use plates for walls, easy to fabricate. Tip: Go mild steel when welding heavy and loads stay moderate. It cuts fab time by half versus alloys.

Factories churn out gear with these plates daily. Strength without extras keeps output high.

Automotive and Transportation Sectors

Trailer frames bend from mild steel plates for tough roads. Chassis in trucks reinforce with them for haul strength. Inside cars, they stiffen doors without adding weight.

Utility vehicles like ATVs use plates for underbody guards. Beyond fancy panels, mild steel handles the grunt work. It welds to high-strength parts seamlessly.

Transportation booms on this reliability. Plates keep fleets rolling year after year.

Conclusion

Mild steel plates nail the sweet spot of strength, ease, and price. Low carbon unlocks ductility and weldability that high-end alloys can’t match for basic jobs. You get a material that forms fast and lasts long with simple care.

Controlled elements like carbon under 0.3% define its friendly nature. From bridges to machines, it builds the backbone of our setups. Despite fancy new metals, mild steel rules infrastructure.

Next time you spot a sturdy build, think of mild steel plates at work. Choosing the right mild steel plates supplier ensures consistent quality, accurate specifications, and proper surface coatings for long-lasting performance. Whether for construction, fabrication, or manufacturing, sourcing from a reliable mild steel plate manufacturer or distributor provides a strong foundation for dependable results.