Understanding Metal Embossing Machines

One of the traditional and very effective methods of producing raised or recessed characters and patterns on metal surfaces is a metal embossing machine. It has been in widespread use for decades in industries where a permanent mark and durability is of paramount importance.

Key Applications

- Industrial Identification: Ideal in designing metal tags, plates and labels on machines, tools, and equipment.

- Asset Tracking: Embossed metal tags can be read even under extreme conditions.

- Compliance Labels: Most industries need the ability to be permanently marked in a way that does not fade in heat, chemicals or weather.

Benefits

- Indelible permanent marks.

- Available on many different metals.

- Simple maintenance in comparison to digital marking technologies.

When durability and legibility are of the highest priority, metal embossing machines are the best.

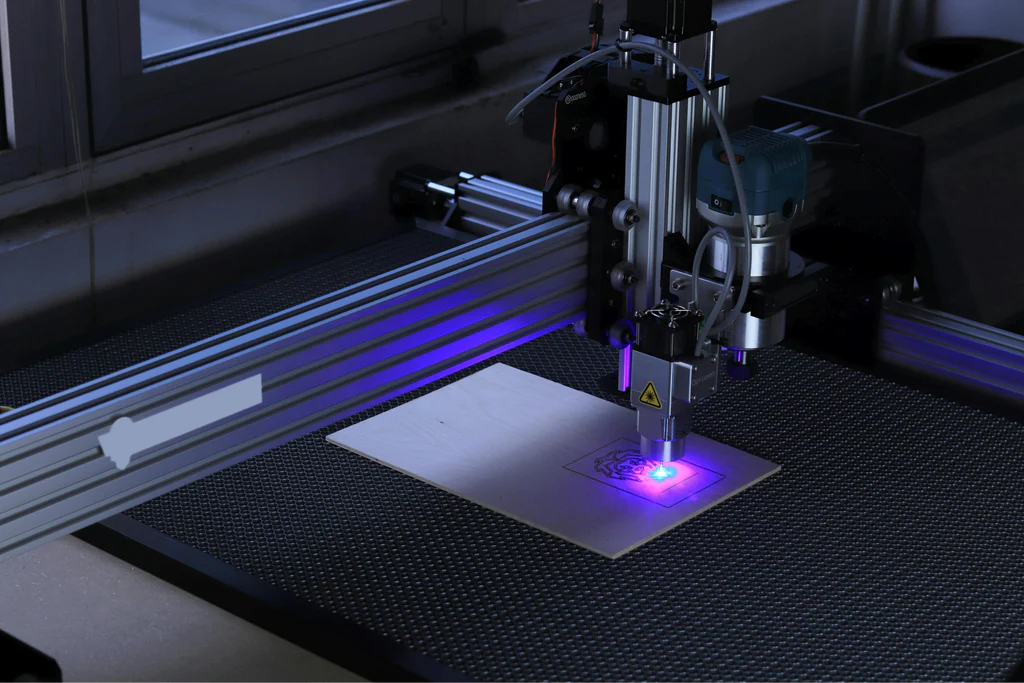

Exploring Laser Marking Machines for Metal

A laser marking machine is a metal machinery that needs high-level laser technology to engrave, etch, or mark the surface. The laser marks surfaces permanently with heat and light as opposed to physically modifying the surface such as embossing.

Common Uses

- Branding of the products: Barcodes, QR codes and Logos can be scribbled with utmost clarity.

- Medical Devices: Marking with high accuracy makes UDI (Unique Device Identification) standards.

- Electronics & Automotive: Marking of small components is possible without their structural ruin.

Advantages

- Very tight and detailed markings.

- Non-contact process, cutting down wear and tear.

- Quick, efficient and suitable for high volume production.

- Embossing not possible to emboss, can mark complex designs.

The laser marking machine that is appropriate to use in industries that require detail, customization, and speed is the metal version.

Which One Should You Choose?

The advantages of both technologies are also distinct and the decision to use them will rest on your industry requirements:

- Use a metal embossing machine when you require heavy-duty tags, compliance plates or labels that will have to survive under harsh conditions.

- When there is a need to be precise, brand, or a large-volume of customized production rather than a mass-production, consider using a laser marking machine on metal.

Final Thoughts

Industries such as manufacturing and healthcare, as well as, aerospace and defense are necessitating permanent identification. Whether you prefer to use a rugged metal embossing machine or a metal laser marking machine depending on precision and detail, both technologies offer dependable options when it comes to the long-term marking solutions.

Through their strengths, businesses are able to invest in appropriate equipment in order to generate efficiency, compliance, and excellence in product identification.