A few years back, a century-old office building in downtown Chicago was about to begin its transformation into a co-working space. However, like so many commercial retrofit projects, it faced a familiar set of challenges – no accurate drawings, tight service shafts, and outdated electrical, plumbing, and fire systems. Until any pipe could be replaced or duct re-routed, the team needed to get a handle on the situation fast. That’s when MEPF Scan to BIM Services completely changed the equation.

Retrofit projects are becoming increasingly important in commercial buildings. Whether it’s to upgrade energy efficiency, adhere to new safety code requirements, or adapt spaces for new use cases, retrofits are more common than in the past. In fact, Autodesk claims that “in the U.S. alone, $31.3 billion in rework was as a result of inadequate project data and miscommunication in 2018.” This is a costly problem that retrofits attempt to minimize.

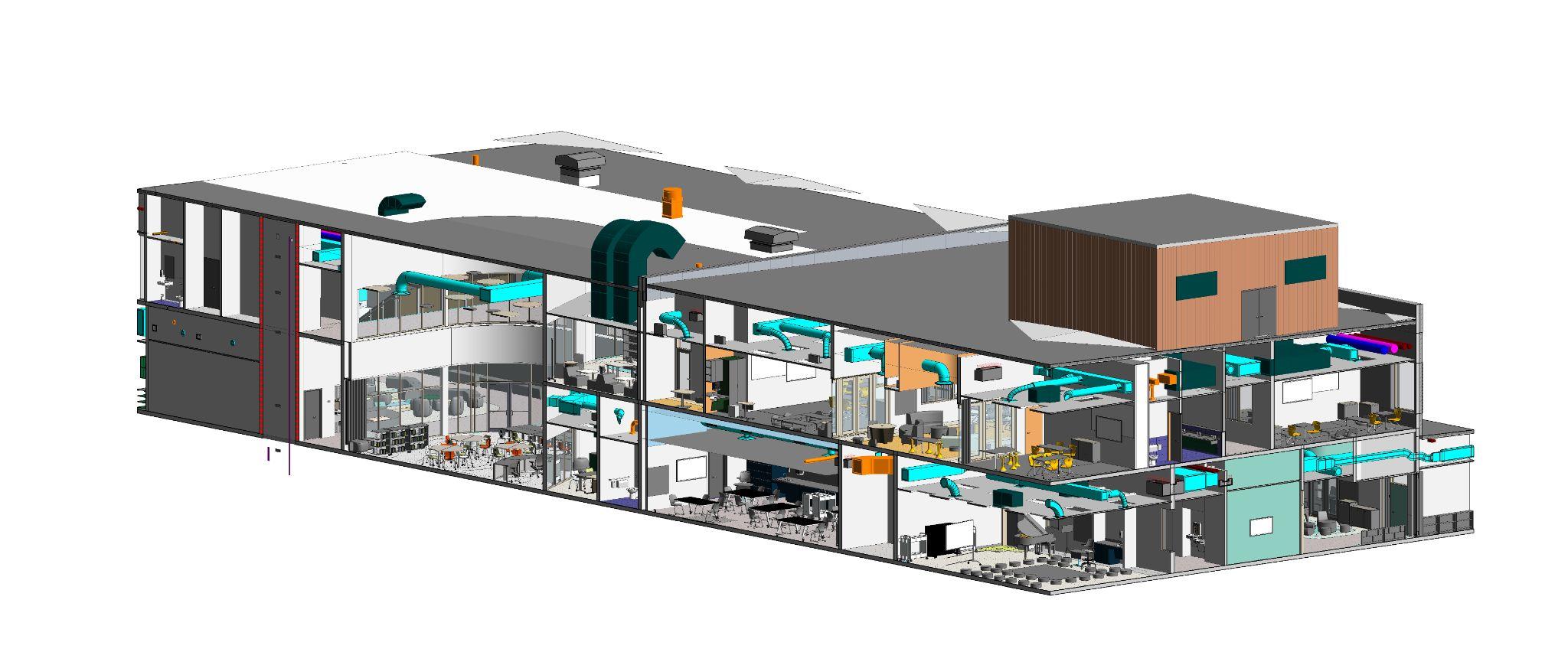

MEPF or Mechanical, Electrical, Plumbing, and Fire protection systems are the lifeblood of a commercial building. Without as-built documentation, retrofitting those systems is like working blind. That’s where MEPF Scan to BIM Modeling comes into play, capturing the existing condition with millimeter accuracy, and converting it into intelligent 3D models. It’s helping architects, engineers and contractors transform commercial buildings with clarity and confidence.

Challenges in Retrofitting Commercial MEPF Systems

Retrofitting MEPF elements in commercial buildings is rarely the straightforward undertaking that it may seem. These systems are frequently subordinate to considerable obstructions, often highly integrated into complex structures, which makes planning and delivery of the work difficult. In the absence of trustworthy data, even the most experienced teams can leave themselves vulnerable to costly delays.

Here are some common challenges:

- Incomplete or dated as-built information: Many older commercial buildings have no updated records about the method of construction of the MEPF. Engineers must either rely on a best guess method or invasive inspection methods, which may elevate risk and uncertainty.

- Congested MEPF spaces: Service shafts and utility corridors are compact and often occupied with multiple overlapping systems. Manual surveys are already difficult and potentially dangerous environments to operate in, and can be made that much worse by activities associated with carrying out retrofitting work.

- Risk of damaging existing services: Without sightlines into what is being retrofitted, in many instances, happening to a system that is still live in the building can result in unintentional severing or damaging of services, which results in unforeseen downtime or unsafe conditions.

- High Coordination Requirements between Disciplines: Mechanical, electrical, plumbing and fire protection systems connect at various points throughout the project. Hence, updating each of their systems in concert requires very precise coordination.

- Time and Cost Overruns from Construction Stipulations: Several construction stipulations can affect the project timeframe and budget, notably unforeseen site “conditions” that will cause the timeline and budget constraints to go south quickly.

MEPF Scan to BIM Services completely solves this issue by providing accurate, clash-free model information. With MEPF Scan to BIM Modeling, when teams go to construct the MEPF system, they will be able to plan sequences accurately, without gaps in information and avoid costly rework.

Functions of MEPF Scan to BIM Modeling in Retrofit Projects

MEPF Scan to BIM Services can be revolutionary for teams working on commercial retrofit projects by offering clarity in situations that were previously unclear. MEPF Scan to BIM can offer teams the opportunity to convert the real-world site conditions into intelligent digital models because it provides the teams with a high definition documentation of poorly defined or existing MEPF systems. What this means in practice is that the teams can plan, coordinate, and execute across all disciplines.

Here is how MEPF Scan to BIM Modeling supports a successful retrofit:

- High Fidelity Point Cloud Document: By laser scanning the current MEPF systems, teams will obtain the precise geometries even at inaccessible sites that involve ‘clutter’ and tight spaces, or at unverified conditions. There is no guesswork involved! This means teams will be working with verified site conditions.

- Clash Detection Prior to Construction: Having accurate models of mechanical, electrical, plumbing and fire protection systems enables the project team to perform clash detection before they start work on site. This process can help eliminate conflicts before they occur on site, thus helping to mitigate costly change orders.

- Creating an As-Built 3D Model for Detailed Planning Activities: Scan to BIM creates an as-built digital twin or digital model of the existing building. This as-built model provides the basis for the design of retrofit strategies relevant to current conditions on the building site.

- Enabling Prefabrication and Modular Solutions: The result is reliable dimensions and layout so prefabricated elements can be designed off-site and installed with confidence, ultimately reducing time and disruption on site.

- Allowing Coordination by Trades: The advantage of all stakeholders – architects, structural engineers of record, mechanical, electrical and plumbing (MEP) contractors and owners alike – can use a shared 3D model representation of the building, leading to better communication and alignment for the same project objectives.

Using MEPF Scan to BIM Services makes retrofits safer, faster and far more efficient.

Top Benefits of MEPF Scan to BIM Services for Retrofit Projects

MEPF retrofit projects have an inherent layer of complexity built-in with new systems being blended with existing building infrastructure. MEPF Scan to BIM Services add great value and specificity, providing benefits to every phase of the project.

Accurate As-Built Documentation

Laser scanning documents the existing MEPF systems to a great level of detail, then BIM modeling converts it to accurate 3D documentation. This does away with a lot of guesswork and provides teams with sound real-world information from the very beginning.

Clash Detection & Conflict Resolution

With a digital twin of the existing systems, teams can perform clash detection and resolve conflicts early on in the process and actually before the construction phase. This catches conflicts between the new systems and the existing systems so that the team can adjust during design and rework the design before expensive rework on-site occurs later on.

Improved Coordination

By preparing a unified and shared 3D model with the architectural, structural, and MEPF components, the team is able to unify and confirm the validity of their designs across all divisions. This diminishes miscommunication and design errors.

Savings on time and costs

Better planning leads to fewer surprises in the construction phase. This removes delays, reduces total labor hours, and reduces wasted materials resulting in savings that can be measured.

Regulatory Compliance & Safety

Accurate models ensure that retrofits comply with current building codes, fire regulations, and accessibility/ADA codes and make it safer and compliant to use from day one.

When you work with MEPF Scan to BIM Modeling, we are able to move towards a better and more accurate result with more accuracy and personal control, in a forth-right way on retrofit projects.

Five Best Practices for Applying MEPF Scan to BIM

It is important to realize the value of MEPF Scan to BIM Services for the retrofit and it is equally important to apply a few best practices that are going to ensure data accuracy, modeling consistency, and team collaboration.

Here are the important things to consider:

1. Select the Right Scanning Partner

You want to work with a provider who has experience with complex MEPF environments. They should provide you with clean registered point clouds & good design level MEPF Scan to BIM Modeling provided to the project timeline and accuracy requirements.

2. Determine a Clear Scope and Level of development (LOD)

Define which systems you need to model such as HVAC, piping, conduits, fire protection, etc. Also to a particular LOD. Knowing the volume and scope of the retrofit will help deter scope creep, ensure that model development can be controlled, and make sure the model you’ll build to meet its use whether it may be: design, prefabrication, maintenance.

3. Coordinate Multi-disciplinary Efforts

Ensure that architectural, structural, and MEPF scans and corresponding models are aligned to a common origin before a high level of construction documents are produced. Early scans allow for the identification of potential clashes, better coordination of designs, and good contingent to integrate during construction.

4. Leverage Cloud-based Collaboration Platforms

Cloud-based collaboration models, such as BIM 360 or Navisworks, allow teams to load the models, provide comments, log issues and solutions and update the models in real time. Real-time shared content makes the team experience more collaborative, transparent, and increases the speed of decision making.

5. Validate the Model Before you Construct

Before starting the construction, validate on the job site the BIM model using control points or layout. Verification of the model ensures that it aligns with the existing conditions, ultimately reducing rework of incorrect material. Following these best practices will help ensure that your Scan to BIM implementation is enabling accuracy, efficiency, and project success.

Conclusion

Retrofitting commercial buildings is no longer a process riddled with uncertainty and guesswork. MEPF Scan to BIM Services provides project teams with accurate as-built data, coordinated 3D models, and vision to identify issues preemptively before they evolve into costly problems on site. There are myriad benefits to everyone associated with retrofitting – facility managers, engineers (including MEPF), contractors, and owners will all need to experience better planning, reduced risk, and accelerated timelines.

This technology signifies a shift away from reactive fixes, based on the data available to us, to proactive data-driven decision-making. By implementing digital solutions, including MEPF Scan to BIM Modeling, teams can enter retrofit projects with clarity, confidence, and control.