The construction industry has long faced inefficiencies, waste, and expensive rework. According to the U.S. Environmental Protection Agency (EPA), “600 million tons of C&D (construction and demolition) debris were generated in the United States in 2018, which is more than twice the amount of generated MSW (municipal solid waste)”. The main contributor to these issues is installing MEPF (Mechanical, Electrical, Plumbing, and Fire Protection) systems by traditional means on-site, where often, errors in coordinating drawings, site constraints, or inconsistent workflows will sub-optimally lead to delays, waste, or redundancy, which causes the job to be more expensive than anticipated.

The answer to these challenges is prefabrication and modular construction. Shifting MEPF assembly from the job site, where stakeholders often possess less control over precision, quality, and scheduling, to a controlled off-site assembly facility. However, scaling this will still require a complete digital solution that can relay the correct information with precision, coordination, and the ability to execute.

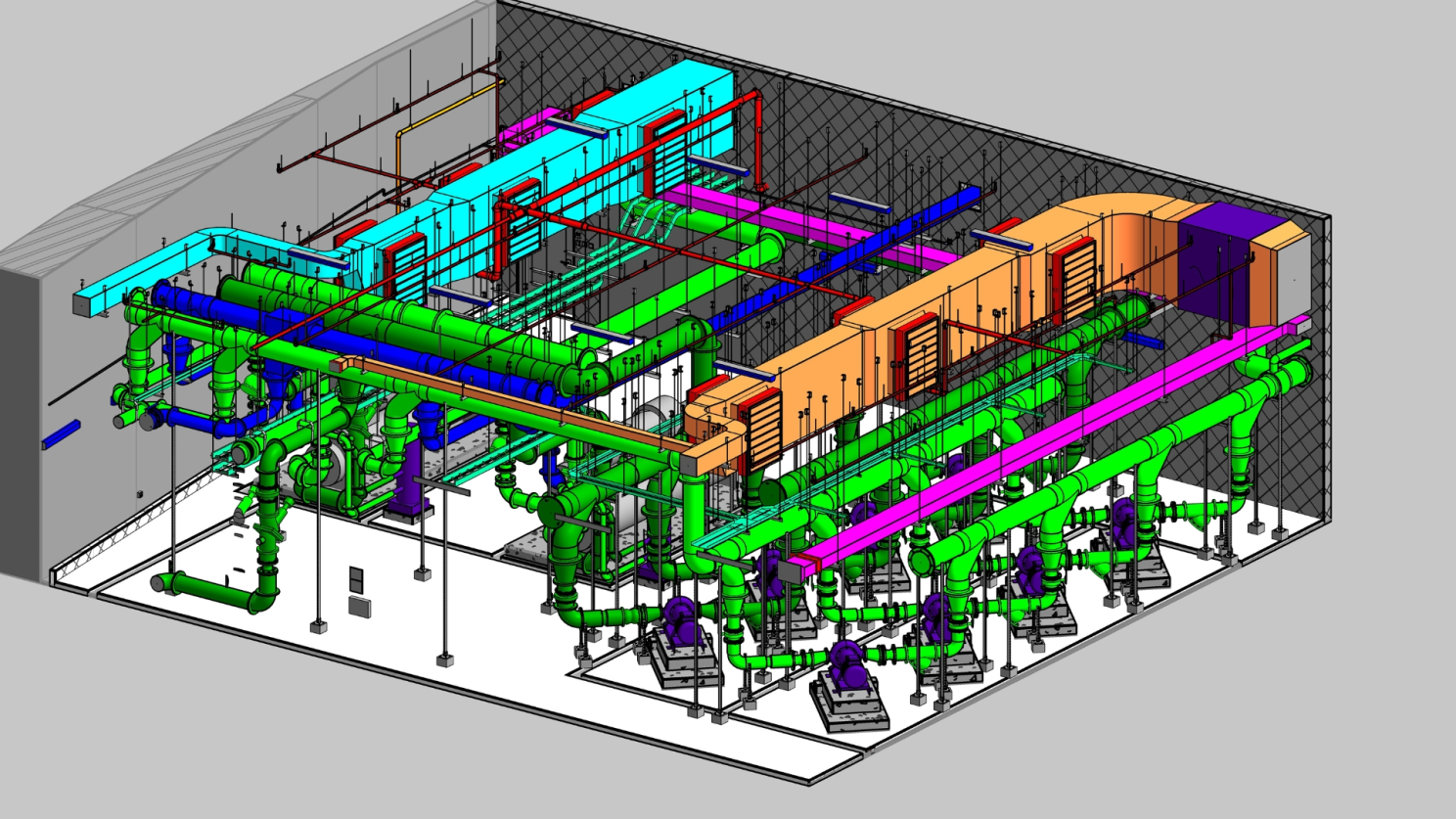

Introducing MEP BIM for Modular Construction, the latest technology is here that allows MEPF systems to exist in a data-rich, coordinated 3D environment. MEP BIM services allow design teams, fabricators, and contractors to build, test, and improve modules in a virtual environment before they are manufactured, resulting in a significant reduction in error and waste.

This blog discusses MEPF BIM services that are changing the pace of prefabrication and modular construction while increasing efficiency, sustainability, and long-term project health for all stakeholders.

Understanding MEPF and BIM

So, what is MEPF?

The MEPF part of the process covers the backbone systems that make a building functional, safe, and habitable:

- Mechanical (HVAC): Heating, ventilation, and air conditioning systems, along with pumps, boilers, and chillers, regulate the indoor climate and quality of air.

- Electrical: Power distribution, lighting, and communications systems keep the building working.

- Plumbing: Water supply, drainage, and gas lines that provide sanitary conditions and convenience.

- Fire Protection: Sprinkler systems, detection devices and alarm systems that ensure the safety of occupants and property.

As you can see, each of these disciplines is inter-relational and should be coordinated carefully in the planning phases of the design process.

What is BIM?

Building Information Modeling (BIM) is more than just a 3D visualization software; it is an intelligent and data-rich process that creates and manages information during the lifecycle of a project. BIM and the data it allows can be used from design to construction to facility management by linking geometry to metadata, assisting practitioners and engineers in collaboration, accuracy, and assessments.

The Convergence: Why MEPF is Well Suited for BIM

- MEPF systems are the most complex systems in a building and consume the most space physically.

- Coordination across trades of the MEPF systems is paramount to avoid clashes and costly rework.

- Rich datasets are needed for fabrication, installation, and maintenance.

It is easy to see why MEP BIM services are critical—helping teams navigate a streamlined design process, improving constructability by discovering and managing information from BIM, and providing confidence with prefabrication or modular construction.

What is Prefabrication & Modular Construction?

Prefabrication is the manufacturing of MEPF components, such as ductwork, piping racks, electrical risers, or sprinkler assemblies, off-site in a controlled environment. These components are fully fabricated and ready to install when they arrive on-site, offering improved accuracy and a reduction of labor on-site.

Modular construction takes prefabrication a step further and manufactures entire building modules or units off-site, including bathrooms, kitchens, or utility corridors, which are assembled on-site, similar to building blocks.

Benefits of Prefabrication and Modular Construction

- Speed: Off-site work can happen in parallel with site preparation, resulting in faster project timelines.

- Reduced Waste: The controlled factory environment reduces errors and waste of material.

- Improved Safety: Reduction in on-site work reduces the risk exposure to workers.

- Cost Savings: Streamlined processes reduce labor rework, delays, and costs.

In combination with MEP BIM services, project teams will be able to design, coordinate, and optimize these prefabricated modules digitally before fabrication to ensure on-site assembly is step-wise and efficient.

Role of MEPF BIM Services in Preabrication & Modular Construction

The effectiveness of prefabrication and modular construction relies on accuracy, coordination, and predictability – these three areas are where MEP BIM services provide value. BIM creates data-rich collaborative datums that streamline the design-to-fabrication workflow to be more efficient and predictable, while allowing construction execution on-site to be steadily more seamless.

Primary MEP BIM Roles for Modular Construction:

- Accurate 3D Model for MEPF Components: BIM creates intelligent clash-free 3D models of mechanical, electrical, plumbing, and fire protection systems. These models form the basis of accurate off-site fabrication, leaving little to no room for guesswork.

- Clash Detection and Interdisciplinary Coordination: MEPF systems take up a lot of space, and proper coordination with architectural and structural elements is imperative. BIM can indicate or identify which clashes exist in the model and help resolve those clashes in a virtual environment, thereby saving time, materials, and costly rework during installation.

- Fabrication-ready drawings and Spool Sheets: By utilizing MEP BIM services, contractors are given shop drawings, spool sheets, and instructions for assembly. These documents allow the prefabrication team to manufacture ducts, pipes, or racks accurately.

- Information-rich Models for Logistics & Installation Planning: BIM embeds information like material specifications, dimensions, and sequencing directly into the model, which are useful for fabricating, transporting, and installing the ‘modules’ on-site. The modules are being designed, ensuring that when they are transported to the site, they fit well together.

- Virtual Simulation of Modular Construction: BIM offers stakeholders the opportunity to virtually simulate modular assembly prior to manufacturing the components. The stakeholder is visualizing the construction efficiency as well as risk to the installation right from the start, using an assembly timeframe in virtual space. This virtualization raises the opportunity for better sequencing, coordination on-site, as well as managing risks associated with installation.

When project teams utilize MEP BIM for modular construction, they have the confidence to go off-site with complex MEPF systems, a level of efficiency that will fast-track a project, improve safety and enable cost savings.

Conclusion

BIM is not only a design tool; it serves as an enabler of successful prefabrication and modular construction, which is fundamentally changing how MEPF systems are designed, built, and assembled. With the combination of precise digital data and off-site production, BIM has the potential to reduce waste, save costly mistakes, and save time with fast-track construction.

Companies adopting MEP BIM services are, in fact, allowing their teams to coordinate and plan complex building systems with unparalleled accuracy. In doing so, they are transforming the construction project delivery process to more innovation, speed, safety, and sustainability. Therefore, MEP BIM for modular construction is the future and present of smart building delivery.