The industrial sectors of food processing and pharmaceuticals and chemical manufacturing and cosmetic production and dairy processing use a stainless steel rotary gear pump because it provides durability and corrosion resistance and hygienic engineering. This pump system which uses intermeshing gears to create displacement flow operates successfully for handling viscous liquids because of its dependable performance and precise operating capabilities. The study of pump performance and operational dependability needs to focus on real-world pump system evaluation which requires testing of all pump system components together with their actual field operations.

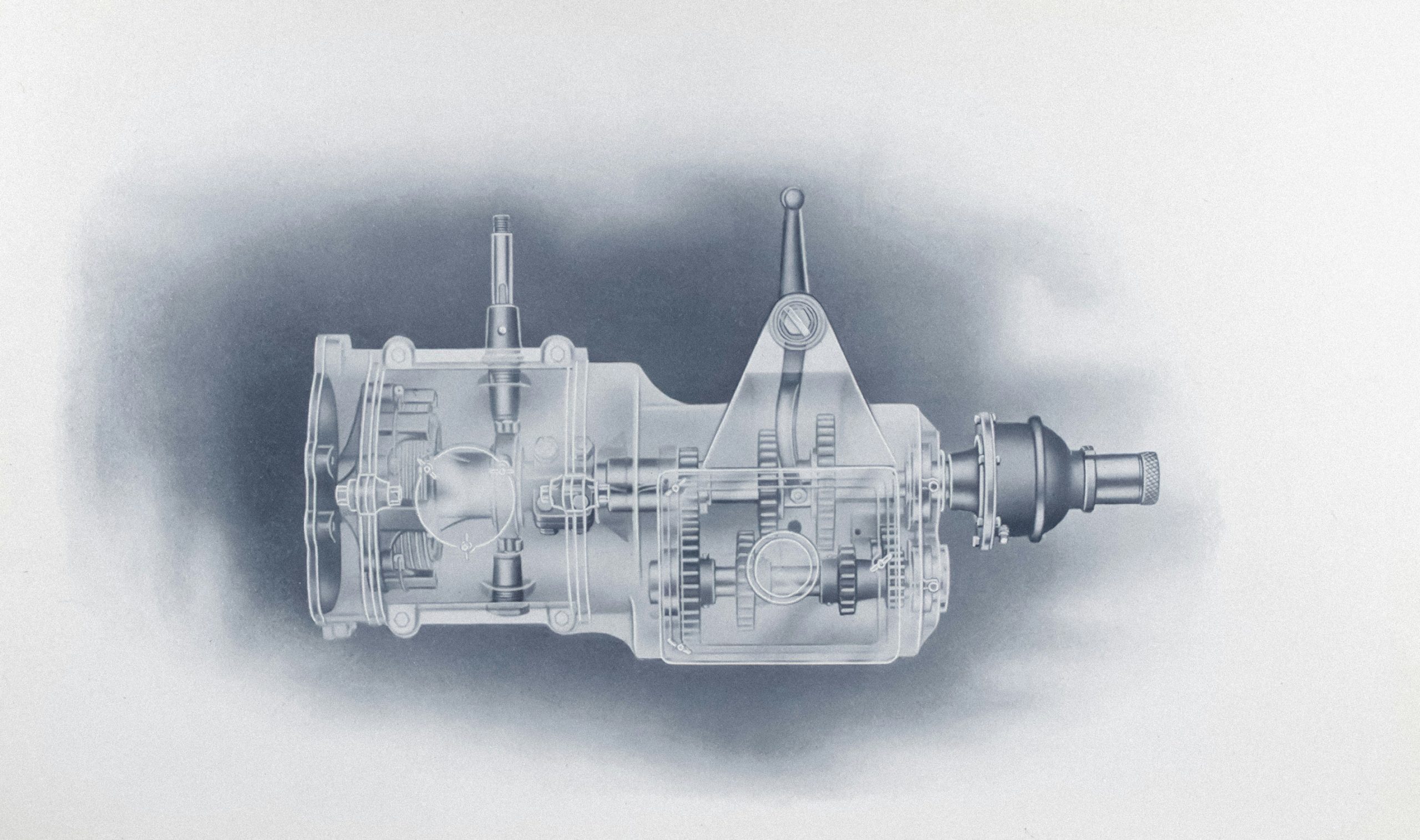

1. Pump Housing (Casing)

The pump housing is the outer body that encloses the internal components. The casing of stainless steel rotary gear pumps uses high-grade stainless steel materials which include SS304 and SS316 to provide strong protection against all forms of corrosion and chemical exposure and high temperature environments.

The housing is precisely machined to maintain tight clearances between the gears and the internal walls. The system achieves proper operation because the pump’s construction creates a sealed space that manages fluid motion while preventing any substantial reverse flow or leakage. In hygienic applications, the casing is often polished to a mirror finish to prevent contamination and make cleaning easier.

2. Rotary Gears

The pump’s primary function depends on its rotary gears which serve as its essential operating component. The system uses these components to produce the fluid motion required by its operations. A typical rotary gear pump consists of two gears:

- Drive gear (connected to the motor)

- Idler gear (rotates freely)

The inlet side of the system generates a vacuum through the gear rotation which operates to bring fluid into the pump. The fluid enters between the gear teeth and the casing which moves it to the outer edge for discharge.

These gears are usually manufactured from hardened stainless steel for strength, wear resistance, and long service life. The precision of the gear design directly affects the pump’s flow rate, efficiency, and ability to handle high-viscosity liquids.

3. Shafts

A shaft serves as the mounting point for each gear. The motor connects to the drive shaft while the idler shaft provides support for the second gear. The shafts exist to control the torque while they keep the gears in their correct position throughout their work period.

The stainless steel rotary gear pumps use shafts that manufacturers construct from corrosion-resistant stainless steel which they polish to decrease friction and wear. Proper shaft design ensures smooth rotation, minimal vibration, and consistent fluid flow.

4. Bearings and Bushings

Bearings or bushings provide support to rotating shafts while maintaining accurate gear alignment. The system creates reduced friction which enables continuous operation during maximum weight conditions.

Manufacturing these components requires specific materials which depend on their intended use. The available materials for this process include Carbon Bronze PTFE and Ceramic-coated materials.

The food and pharmaceutical sectors use non-lubricated hygienic bushings for their ability to maintain clean environments. The pump system requires high-quality bearings to achieve extended operational life and decreased need for maintenance.

5. Mechanical Seal or Gland Packing

The mechanical seal serves as an essential component that stops fluid from escaping through the rotating shaft. The pump requires a sealing system because the shaft passes through its housing which needs to control pressure and protect against product spills.

The mechanical seals of modern SS rotary gear pumps provide operators with complete leak-proof performance while decreasing their need for maintenance work and proving their safety for use in hygienic environments.

Mechanical seals deliver superior efficiency and cleaner operations than traditional systems which still rely on gland packing.

6. Inlet and Outlet Ports

The inlet and outlet ports serve as the points through which the fluid enters and exits the system. The pump system performance depends on the dimensions and configuration of its inlet and outlet ports.

Stainless steel rotary gear pumps used for sanitary applications in their construction use these ports which include

- Tri-clamp connections

- SMS unions

- Flanged fittings

The hygienic fittings provide installation advantages because they enable quick disassembly which makes complete cleaning possible.

7. Timing Gears (in External Systems)

The advanced rotary gear pumps use timing gears which maintain perfect synchronization between drive and idler gears through non-contact operation.

The system uses timing gears because they enhance operational efficiency while decreasing equipment damage and allowing the system to process fragile materials.

8. Pressure Relief Valve

The pressure relief valve functions as a critical safety component. The rotary gear pump maintains its fluid movement through positive displacement when the discharge line becomes blocked. This condition leads to dangerous pressure accumulation.

The relief valve operates to protect both the pump and piping system by redirecting surplus fluid when system pressure surpasses its designated threshold.

9. Mounting Base and Coupling

The mounting base provides structural support and ensures proper alignment between the pump and the motor. The coupling establishes the motor shaft connection to the pump shaft which allows for power transmission through the system.

Flexible couplings are commonly used to:

- Absorb vibration

- Compensate for slight misalignment

- Protect the pump from mechanical stress

Conclusion

The stainless steel rotary gear pump functions as a precisely engineered equipment system which achieves both durable and efficient and hygienic operational performance. The pump housing and rotary gears and mechanical seal and bearings work together as essential components to deliver effective operation and extended life.

Understanding these key components not only helps in selecting the right pump for specific applications but also simplifies maintenance and troubleshooting. With proper design, high-quality materials, and regular upkeep, a stainless steel rotary gear pump delivers reliable and consistent fluid transfer across a wide range of industrial processes.