When it comes time for the machines to work harder, take on harsher environments and require a tighter degree of accuracy than ever before trying to trust an age old metalworking process is no longer realistic. This is exactly where investment castings India comes in permitting for the production of intricate, near net shape parts that are durable, and can be produced quickly at low cost. Though the process may seem old fashioned, given the historical context of today’s door applications, one can see that its potential is anything but antiquated.

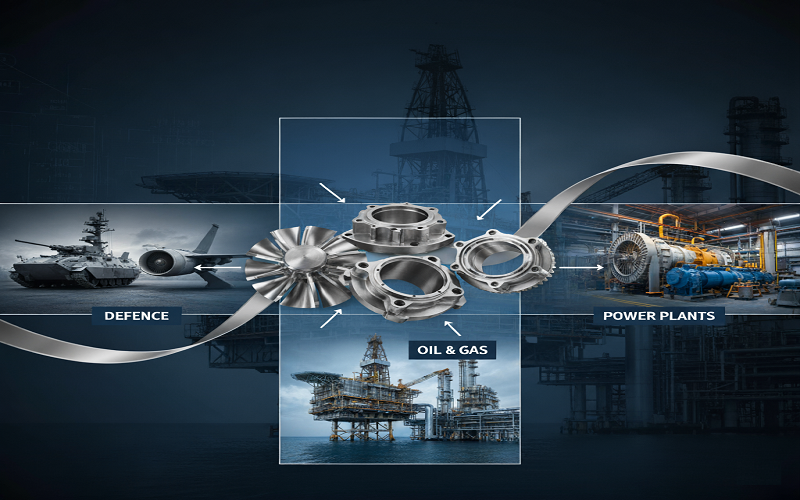

There are several industries and sectors which depend on investment castings of parts for its functioning but three most evident ones are Defence, Oil & Gas and Power Generation. The one thing they all have in common is that they operate under extreme circumstances, with the need for components that won’t fail. There can also be large, downtime or operational losses caused by even small structural failures. This is why these industries are such strong adopters of intricate investment castings.

Investment Castings in the Defence Sector

The defence industry demands materials and components that can withstand high pressure, corrosion, stress, and unpredictable wear. This is not limited to weapons and ammunition almost every defence mechanism uses precision metal components. One of the biggest challenges in defence design lies in maintaining strength while keeping the structure lightweight. Investment casting solves this problem better than many traditional processes.

Today, investment casting is commonly used for:

- Missile and aircraft structural parts

- Turret and tank components

- Trigger mechanisms and firearm assemblies

- Gear housings and control systems

- Defence communication equipment

- Marine and marine hardware such as valves, pumps, and propellers

The ability to cast metals like stainless steel, special alloys, and heat resistant super alloys makes investment casting suitable even for extreme battlefield or aerospace conditions. What also adds value is the design freedom. Defence engineers can build parts with internal passages, sharp edges, undercuts, and thin-wall structures without compromising strength. Since prototypes and production parts can be developed with the same mold precision, it supports faster defence R&D and more reliable mass production.

Investment Castings in the Oil & Gas Industry

Oil and gas are still among the toughest industrial environments for metal. The harsh environment including seawater, high pressure gases, chemicals and abrasive fluids requires that materials must be able to resist corrosion and erosion for long period. When equipment craps out, production stops and accidents become a real threat. For this reason, the oil and gas industry has long shifted toward investment casting for safety critical components.

Some of the key applications include:

- Valve bodies and valve seats

- Impellers and pump components

- Flow meters and pipeline connectors

- Drill bits and downhole tools

- Gear and turbine parts

- Hydraulic system components

Many of these parts must operate deep underwater, inside drilling rigs, or on high-temperature refinery systems. The beauty of Investment Castings India lies in producing leak-proof, pressure-resistant bodies with smooth surfaces and excellent metallurgical integrity. When pipeline networks or control systems run 24/7, small imperfections can become catastrophic. Precision investment casting removes that risk by protecting every millimetre of the component with dimensional consistency.

Another reason the oil and gas industry strongly favors investment casting is versatility. Whether the requirement is for a small batch of customized parts during exploration or bulk production for refinery installations, both can be executed cost effectively without compromising performance.

Investment Castings in Power Plants

Power generation especially in thermal, nuclear, and hydroelectric plants involves high temperatures, combustion exposure, rotational impact, and mechanical vibration. Components need to perform under challenging conditions while supporting efficiency and energy output. A power plant’s operational continuity depends heavily on the performance of its turbines, pumps, boilers, and control mechanisms. This is where investment casting proves itself beyond doubt.

Typical applications include:

- Steam and gas turbine blades

- Combustion system components

- Boiler and pressure vessel parts

- Pump housings and impellers

- Heat-resistant and corrosion-resistant fittings

- Cooling system hardware

Turbine blades are a special example. They rotate at extremely high speeds and handle massive amounts of heat. A tiny crack or irregularity can instantly disrupt the energy cycle. Investment casting supports the manufacturing of such complex curved blade geometries with thin walls and accurate profiles. Similarly, nuclear plants depend on cast stainless steel and nickel based alloys for radiation resistance, reliability, and low maintenance requirements.

Even renewable power has adopted investment casting. Wind turbines, for example, require strong and lightweight internal components such as hubs, spacers, brake parts, and hydraulic system elements. The longer these parts endure, the more cost competitive renewable energy becomes.

Why These Industries Cannot Operate Without Investment Castings

There are three core reasons why defence, oil & gas, and power plants continue to adopt investment cast parts at scale:

- Dimensional accuracy without machining: Complex shapes are produced with tight tolerance, minimizing material removal and cost.

- Superior mechanical performance: The casting process offers uniformity, density, and surface quality crucial for mission-critical equipment.

- Design freedom for engineers: Parts that cannot be made through forging or machining can be produced using investment casting.

What makes it even more appealing is the cost to performance ratio. Once tooling is created, every subsequent unit is consistent, reliable, and highly repeatable, regardless of volume.

Conclusion

Industrial sectors that depend on unmatched strength and reliability are putting their trust in investment casting more than ever. Precision and robustness are crucial to defense systems that safeguard the nation. The oil and gas industry requires corrosion-resistant, leak-free parts that perform in some of the harshest conditions on the planet. Power plants require consistent performance and resistance to heat so that energy is maintained. Despite their differences, each sector finds the exact blend of complexity, strength, and efficiency they need in investment castings.

Read More : Vibro Sifter Manufacturer and Wholesaler

As industries move toward higher precision and smarter production, the role of investment casting manufacturers India is set to expand further. What began as an ancient metal working process has evolved into a critical enabler of modern engineering, powering some of the world’s most demanding applications behind the scenes.