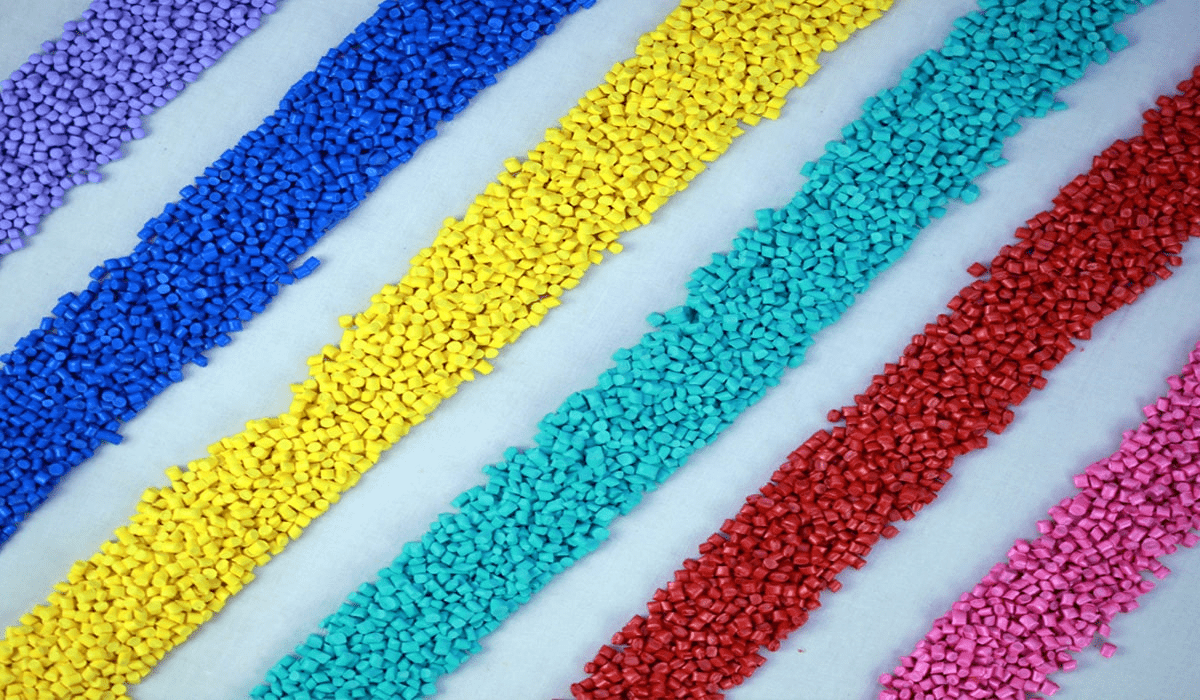

Choosing a competent masterbatch manufacturer can change product operations, product quality, production efficiency, and your bottom line on the sale of the product. Masterbatches are blends of pigments, additives, or fillers in a concentrated condition and play an extremely crucial role in the plastics industry to give color, enhance performance properties, or provide special attributes to polymers. Having lots of choices on hand, especially when you consider an Indian manufacturer of masterbatches, whose industry has come a long way in terms of growth, the following important things must be kept in mind prior to choosing an effective partner.

Knowing Your Exact Requirement

Before beginning your masterbatch supplier search, it is important to specifically clarify your requirements. Considerations may entail the type of polymer being employed, the properties desired, coloring requirements, and performance specifications. Having this knowledge will fine-tune your search for suppliers who specialize in your particular application. The suitable masterbatch supplier would be one that is already familiar with your particular polymer system and application-increased compatibility with better results.

Quality Specification and Certification

Quality certification must be the first consideration in choosing a masterbatch supplier. Check for certifications like ISO 9001, ISO 14001, or other industry standards. A reliable masterbatch manufacturer in India will provide quality certification along with quality management systems. These certifications indicate a manufacturer who is dedicated to maintaining quality in a consistent manner, adhering to standard operating procedures, and continuously improving their operation to international standards.

Technical Competency and Back-Up

Your master batch manufacturer’s technical skills will impact how successful your products turn out. Mark their research and development plant, lab equipment, and technical staff credentials. An ideal manufacturer will technically back you up throughout the duration of your arrangement with them, from formulation development to rectifying production issues. Their work will entail the provision of the material and collaborating with you to maximize your processes so that you can obtain the optimal results.

Capacity and Capability of Manufacturers

Determine the production capacity and manufacturing capability of potential masterbatch producers. Assess their equipment, production variables and scalability for adjusting to your growing needs. A well-known Indian masterbatch producer with a long legacy will possess advanced equipment, a streamlined production system, and the ability to cope with your volume demands without compromising quality or delivery schedules. This ensures the surety of supply, even as your business grows.

Consistency and Batch-to-Batch Uniformity

The uniformity of masterbatches has its specific function: even minor differences can be significant sources of quality problems in your end products. So, inquire from the manufacturer about their quality control procedures, their batch-tested practices, and how they ensure consistency between batches. A conscientious masterbatch producer does a lot of checking throughout each step of the process to make sure you receive products that will perform exactly as you anticipate.

Conclusion:

When selecting a masterbatch supplier, you have to weigh a lot of options, from quality to technical prowess to the environment and value. Taking the time and effort to screen potential partners will be rewarded with benefits through improved product performance, stable supply, and outstanding high-value technical service. Whether it is the search for a masterbatch manufacturer in India or elsewhere, being mindful of these considerations will go a long way in establishing a productive relationship with a supplier, which will be of value to quality and business prosperity.