Opening Context

Modern heavy-duty diesel engines face growing demands for higher torque, enhanced fuel efficiency, and reliable performance. Whether hauling massive loads or completing long-haul journeys, these engines are the cornerstone of industrial and logistical operations. Among these platforms, Caterpillar’s 3406E engine stands out for its robust design and adaptability.

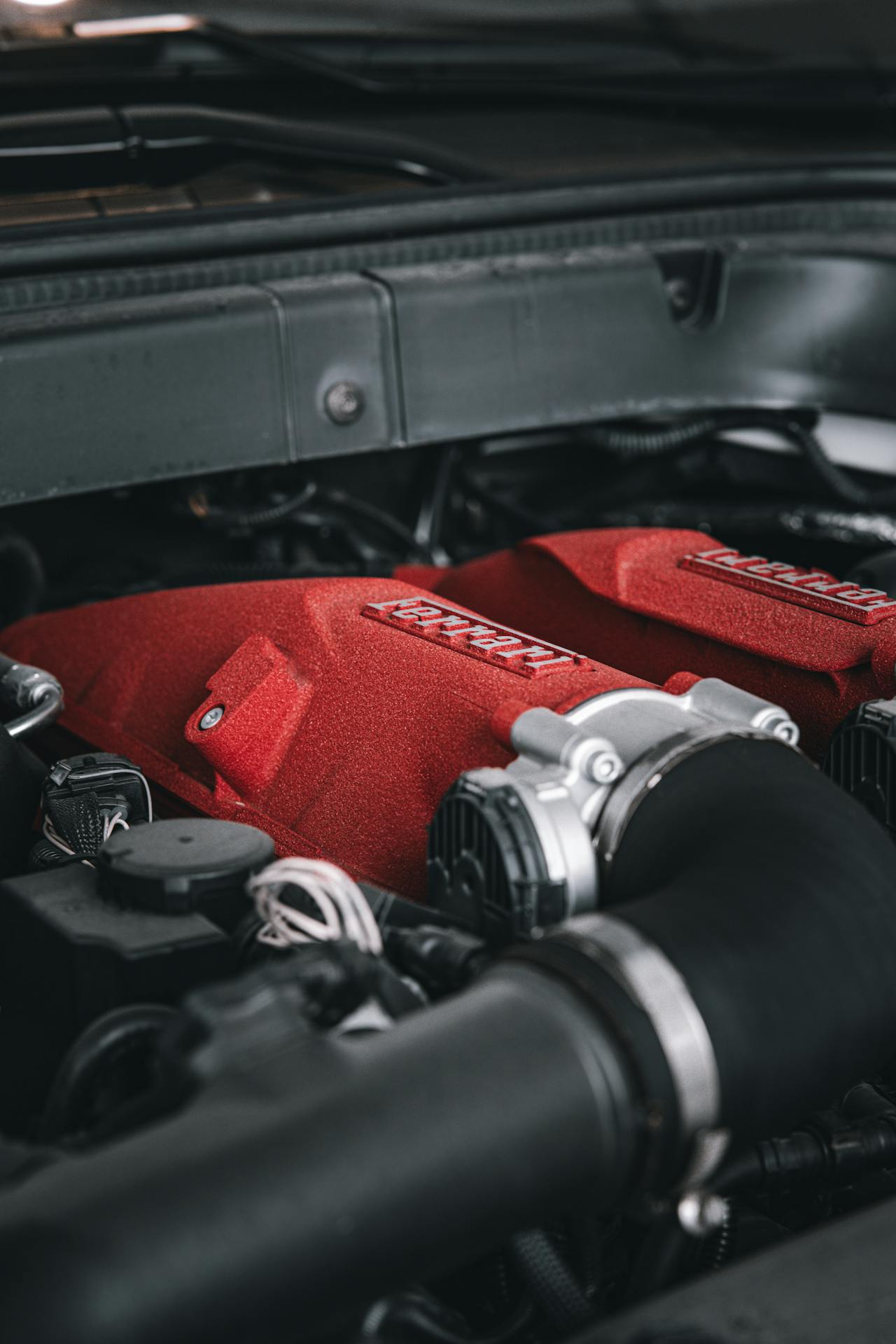

The turbocharger is at the core of the engine’s performance—a key component responsible for delivering power, efficiency, and responsiveness. Improvements and tuning strategies tailored to this turbo system can unlock significant gains, transforming the 3406E engine into a true workhorse. This article explores how modern upgrades and adjustments can address performance challenges and maximize the engine’s capabilities.

Evolution of Turbocharger Technology in Cat 3406E Platforms

The original turbocharger on the 3406E engine was designed to meet basic industrial needs. This stock setup typically featured a standard journal-bearing system and conventional compressor wheel design, operating well under moderate workloads but struggling at higher output levels. While functional, it often fell short of delivering peak performance under heavy-duty demands.

Advances in aftermarket technology brought upgraded components that vastly improved turbo performance. Innovations like billet-machined compressor wheels offer better precision and airflow efficiency. Ball-bearing cartridges reduce friction, enabling quicker spooling. Additionally, thermal coatings on housings help manage heat, reducing the risk of turbine damage during prolonged operation.

These technological breakthroughs provide measurable benefits in real-world applications. Drivers report faster torque response, reduced turbo lag, and improved efficiency under heavy loads. Industrial users benefit from extended durability and better reliability in demanding conditions. Such upgrades have repositioned the 3406E platform as a true workhorse in modern diesel applications.

Identifying Performance Bottlenecks in 3406E Turbo Systems

Stock 3406E turbochargers often face a handful of limitations under rigorous use. Compressor surge—caused by inconsistent airflow—can lead to reduced efficiency. Turbo lag, where boost pressure builds too slowly during acceleration, is another common challenge. Prolonged exposure to high temperatures also stresses the housing, causing cracks or other damage over time.

A typical example is when boost thresholds fail to match RPM curves, leaving users with sluggish low-speed torque and inconsistent power delivery. These issues hinder overall efficiency and create roadblocks for tuning efforts. Recognizing these bottlenecks early allows users to accurately target the upgrades needed to restore balance across performance metrics.

Upgrading Components for Enhanced Boost Response

Giving the 3406E turbocharger a performance edge starts with strategic hardware upgrades. The following components deliver noticeable improvements:

- Billet-machined compressor wheels provide tighter tolerances and smoother airflow compared to cast alternatives.

- Ball-bearing cartridge kits outperform traditional journal-bearing setups by reducing friction and improving spooling time.

- Heat-resistant turbine housings and upgraded wastegate actuators protect parts under high-temperature conditions, enhancing reliability.

One resource for aftermarket components is the 3406e turbo. Advanced parts like these reduce lag, deliver quicker response times, and extend service intervals—all of which are critical in demanding applications. Users can expect performance boosts that translate directly to operational efficiency and durability.

Comparison: OEM vs. Upgraded Components

| Feature | OEM Setup | Aftermarket Upgrade |

| Compressor Wheel Design | Cast Aluminum | Billet Machined |

| Bearing System | Journal Bearings | Ball Bearings |

| Thermal Protection | Standard Material | Thermal Coatings |

| Response Time | Moderate Spool | Faster Spool |

Tuning Strategies for Optimal 3406E Turbo Efficiency

Once hardware upgrades are installed, tuning becomes critical to maximizing the turbocharger’s efficiency. Adjusting controller settings like boost targets and wastegate preloads ensures balanced power delivery. Modifying fuel-injection timing improves torque curves and general drivability.

Use tools like dynamometers to validate results and monitor exhaust gas temperatures (EGTs). Iterative map refinements help dial in optimal settings. Be cautious, though—overboost can stress engine components, while high EGTs may lead to long-term damage. By taking a measured approach, users can fine-tune their system for precision performance gains.

Maintenance Protocols to Prolong Turbocharger Service Life

Upgraded turbochargers require proactive maintenance for sustained performance. Regular inspections to check for shaft play and housing cracks prevent catastrophic damage. Keeping oil feeds clear and clean is critical to ensuring proper lubrication, and installing high-grade filters helps extend oil-change intervals.

Cooling-system upkeep also plays a vital role. Engines used in high-load applications must have efficient temperature control to protect the turbocharger. Diligently following maintenance schedules maximizes uptime and keeps the turbo performing consistently.

Driving Sustained Gains in Heavy-Duty Diesel Engines

Upgrades, tuning, and maintenance together create a recipe for success with the 3406E turbocharger. Each part of the process—from hardware improvement to controller calibration—optimizes performance and reliability.

Owners of 3406E engines should evaluate their turbo systems and consider targeted upgrades for the best results. With every step forward, these engines grow closer to meeting and surpassing the high demands placed on heavy-duty diesel platforms. Investing in improvements today sets the foundation for stronger torque, higher efficiency, and unmatched dependability in the future.