In industries that demand ruggedness, acid resistance, and safe surface, FRP moulded gratings have now been developed as a new generation option. Nowadays, FRP gratings are used extensively as lightweight, highly flexible, and highly durable materials replacing some types of steel in marine, chemical, and construction industries, etc. Let us get into the world of FRP Moulded Gratings Manufacturers, exploring their features, benefits, applications, and why they are a vital choice for modern infrastructure.

What Are FRP Moulded Gratings?

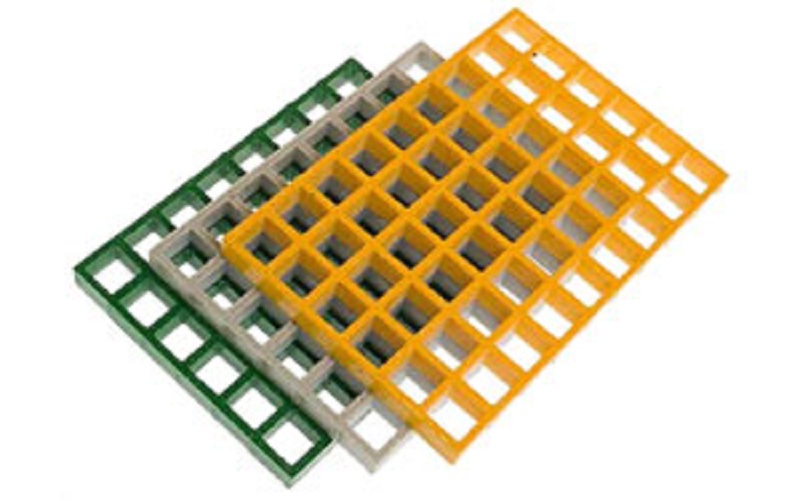

FRP moulded gratings are composite materials manufactured by reinforcing the resin material with fibreglass. These gratings are produced with a moulding process that forms a uniform pattern of squares for the grating structure hence showing enhanced strength from the load bearing capacity.

Key components include:

• Fiberglass: It offers the reinforcement and elasticity of needed in many structures.

• Resin: That provides protection against corrosion and fire hazards.

Features of FRP Moulded Gratings

1. Corrosion Resistance

FRP gratings are chemical immune and hence ideal for corrosive areas such as the water treating station and offshore industry.

2. Lightweight yet Strong

These gratings are much lighter than steel gratings and can therefore be delivered and installed easily without any compromise on strength.

3. Slip Resistance

The sand like surface of the plate also provides safety since there is little or no chance of slippage when the area is wet or oily.

4. UV Resistance

As a result of exposure to sun light, FRP moulded gratings do not wear off or fade.

5. Fire Retardancy

Based on the type of the resin utilised these gratings can effectively pass fire safety requirements.

Applications of FRP Moulded Gratings

FRP moulded gratings are all round products which are applied in different domains. Some notable applications include:

• Chemical Plants

Due to their high resistance to corrosive chemicals they are very suitable for use in chemical processing plants.

• Marine Industry

Because they are non-corrosive, they are widely used in offshore platforms, docks, and ship decks.

• Construction and Architecture

Common application includes in structures such as halls, corridors, galleries and scenic displays, and in staircases in commercial and industrial structures.

• Water Treatment Plants

Due to their abilities to fight both moisture and chemicals, they are widely used at water treatment organisations and plants.

• Power Plants

These gratings can be used where electrical insulation is necessary for the application.

Advantages of Choosing FRP Moulded Gratings Manufacturers

When working with top FRP Moulded Gratings Manufacturers, you gain access to:

• Customizable Options

Manufacturers come up with various sizes, mesh patterns and resin types depending on the client’s needs for the project in question.

• Expert Engineering Support

They involve leading manufacturers in output design and delivery to render sound technical support to the products.

• Quality Assurance

Different manufacturers maintain some international standards that guarantee their tack rooms’ durability and safety.

• Sustainability

FRP gratings are environment friendly products, low in maintenance and reduces service life considerably.

Factors to Consider When Choosing FRP Moulded Gratings Manufacturers

To select the right manufacturer, consider the following:

- Product Range

Make sure that the manufacturer provides grating size, material and design options.

- Quality Certifications

To guarantee the dependability of the goods, search for certificates such ASTM conformity or ISO standards.

- Custom Solutions

Select the manufacturers who can offer individual solutions for specific requirements of various industries.

- Experience and Reputation

Select companies that have been in the industry and have a record of developing good quality FRP products.

Leading FRP Moulded Gratings Manufacturers

Internationally, many manufacturers offer premium quality FRP moulded gratings that meet the industry demands. Let us look into some top producers:

1. Emerald Steel Industries LLC:

Emerald Steel Industries is the UAE based company specialising in producing FRP gratings such as pultruded and moulded gratings. Some of the characteristics that users enjoy about their products include high endurance, good resistance to corrosion and thus is suitable for many markets all over the world.

2. Hebei Juming Import and Export Trading Co., Ltd:

Based in China, this is a manufacturer whose produces strong and light FRP gratings universally used in industries and business.

3. Rajyog Polytech Pvt Ltd:

An Indian manufacturer supplying series of FRP moulded gratings. Organisations competency to quality assemble results with high performing products being sold at reasonable rates.

Innovations in FRP Moulded Gratings

Original strategies are being adopted by manufacturers to enhance the performance of FRP gratings. Key trends include:

1. Fire-Resistant Resins

New resin formulations increase safety due to improved fire retardancy of the chemical compound.

2. Eco-Friendly Options

Widespread use of sustainable materials and processes are apparent in manufacturing circles.

3. Superior Anti-Slip Coatings

Newer developed and modified surface treatments help for providing enhanced grip in dangerous conditions.

4. High-Strength Designs

Pultruded gratings are being prepared for applications that need even higher load carrying capacity.

The Future of FRP Moulded Gratings

Evolving industries wanting even safer and more efficient structures are expected to fuel demand for FRP moulded gratings. Manufacturers presently continue going for the technological advancement that will create products satisfying the modern requirements of industries to keep FRP gratings relevant to the modern engineering solutions.

Conclusion

The FRP moulded gratings have brought a new concept of product in industrial sectors as they are light weighted, highly corrosion resistant, and have versatile application. With their growing popularity across sectors, working with the best FRP Moulded Gratings Manufacturers ensures access to the advanced products designed to meet strict standards. From construction industries all the way to marine and chemical industries FRP gratings offer the best performance, safety and durability.

FAQ

What are the major benefits to be derived if FRP moulded gratings are used in an application?

FRP gratings are specially known to be light weight, highly resistant to corrosion, have very low frictional coefficient and are easy to maintenance.

In what way does FRP moulded gratings differ with steel gratings?

They are lighter, more corrosion resistance and safety in the electrical insulation application.

Can FRP moulded gratings be customized?

Yes, manufacturers do provide the size, resin type and mesh patterns for customization.

What industries commonly use FRP moulded gratings?

They are also employed in marine, chemical, construction and power generation industries.

Are FRP moulded gratings environmentally friendly?

Yes, they are sustainable because they have a long life cycle, minimal maintenance and are made from recycled material.