Fibre Reinforced Plastic (FRP) gratings are just the perfect solution for the industries throughout the India because of their durability, tensile strength and they hardly get corroded. As industries grow, the demand for FRP gratings India is surging, with manufacturers offering innovative designs and customised solutions to meet various industrial needs.

What Are FRP Gratings?

FRP gratings are light stiff structures formed from glass fiber and roofing system resin. These materials are further laminated in order to form a perfect product that is strong, corrosion repellent, and an electrical insulator. Due to these characteristics, they are appreciated in many branches and are preferred because of their high strength to weight ratio.

Features of FRP Gratings:

Durability: for effective, lasting wearing and which can easily withstand wear and tearing.

Corrosion Resistance: High performance in corrosive chemicals as well as in extreme weather conditions.

Lightweight: They are more manageable and easy to install as compared to other metals such as steel.

Non-Conductive: Maintains electrical safety essential in industries.

Low Maintenance: Low maintenance is needed thus cutting the overall expenses of running the organisation.

Applications of FRP Gratings India

FRP gratings are widely used across industries, including:

1. Industrial Platforms and Walkways

FRP gratings serve as safe and long lasting platforms in chemical factories, oil mills, and manufacturing factories. They can easily resist high traffic density since they have a non-slip surface and are very strong.

2. Water Treatment Plants

In water and wastewater treatment systems, FRP gratings are mostly applied on walkways and covers. Some of these advantages even include their ability to withstand moisture and chemicals, thus durableness.

3. Marine shipping and Offshore Operations

Marine environment characterised as salty and humid and thus FRP gratings are the common in marine applications. They are common in the ship decks, ports and even offshore platform facilities.

4. Construction Industry

In most structural designs; be it a bridge or column or any other architectural creation, FRP gratings provide strength as well as beauty.

5. Electrical and Power Plants

They have no conducting nature and therefore they are ideal safety measures in electrical plants and stations.

Types of FRP Gratings

FRP gratings come in different types, each designed to meet specific requirements:

1. Molded FRP Gratings

These are created by using resin and glass fiber and laying them in a mould. They provide equal strength in all directions and have application where there is high corrosive tendency.

2. Pultruded FRP Gratings

These are manufactured by drawing separate glass fibres through the resin and are suitable where normal loads are to be supported because of their strontium.

3. Custom FRP Gratings

The manufacturers themselves in India offer solutions that can be individualised according to size, shape, and type of resin.

Benefits of Using FRP Gratings India

1. Cost-Effective

FRP gratings therefore are more expensive to purchase than traditional materials, but they will last longer and require much less maintenance

2. Safety

They reduce chances of workers slipping and are non-conductive particularly beneficial in dangerous settings.

3. Environmental Resistance

FRP gratings are heat and UV resistant; the material is also resistant to chemical attack and can serve various Indian climatic conditions.

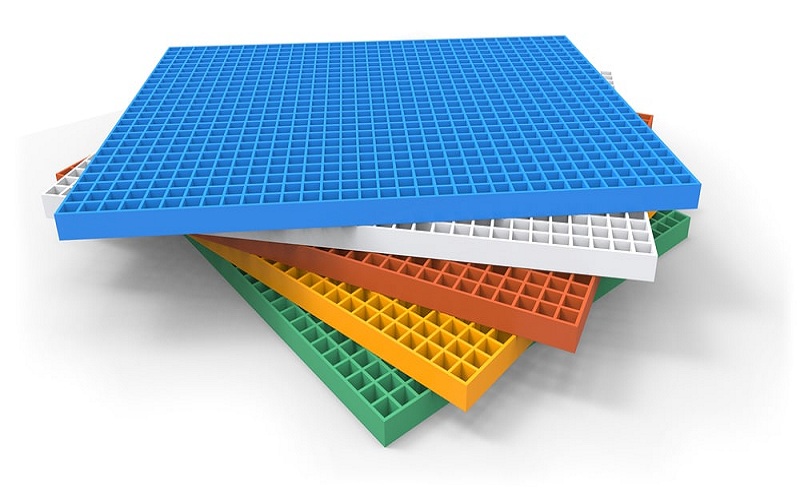

4. Customizable Designs

FRP gratings can be customised according to the requirements with regard to size, colour and strength.

Top Manufacturers of FRP Gratings India

The growing demand for FRP Gratings India has led to the emergence of several reputable manufacturers. Some notable names include:

EPP Composites: We are specialised in custom-shaped moulded and pultruded FRP gratings.

FiberTech Composite: Provides a variety of long lasting and adjustable products.

Aeron Composite: Niche product manufacturer: corrosion resistant FRP gratings for industrial applications.

Sintex Plastics: Real for conventional and non-conventional application for different structures.

Tuflex India: Popular for their light weight and high strength of gratings.

Factors to Consider When Choosing FRP Gratings

1. Load Capacity

Depending on the load that will be put on the grating, it is appropriate to consult the type and thickness which should be used.

2. Environmental Conditions

Some of the measures possibly include; The chemicals used The amount of UV radiation to which the clothes may be exposed The amount of moisture the clothes may be exposed to.

3. Size and Customization

Select those manufacturers who can provide you a solution according to your specific needs.

4. Resin Type

Each resin has its level of corrosion resistance, fire rating, and UV protection. Choose the one which can suit you the best.

Maintenance Tips for FRP Gratings

FRP gratings require minimal maintenance, but regular checks ensure their longevity:

Clean Regularly: Clean to retain its anti-slip status especially the floor to ensure that it has no debris.

Inspect for Damage: Look for the presence of greater crack, or the most worn out area especially for areas that are normally under high loads.

Avoid Overloading: One should maintain the given load carrying limit in order to avoid straining it.

Future of FRP Gratings India

As industries shift towards sustainable and efficient solutions, the demand for FRP Gratings India is expected to rise. Shoes production combined with environmentally friendly production procedures and being fully recyclable make them the choice of the future from the standpoint of worldwide ecological objectives.

Conclusion

The latest FRP gratings have done a lot to change the face of Industrial applications throughout India due to its features like high durability, safety, and flexibility. Thereby FRP gratings have an application that meets basic requirement of construction, marine or electrical industries. As the market evolves, companies have the opportunity to cooperate with the best manufacturers who provide equipment for specific business requirements.

FAQ

1. Why would one want FRP gratings instead of steel?

Though far more resistant to corrosion and electrical conductivity, FRP gratings are far less heavy than steel.

2. Is it possible to make alterations to FRP gratings?

However, manufacturers of cable trays in India can well provide their clients with cable trays made to the size, shape and for particular use.

3. Where can we find FRP gratings?

Due to their flexibility and hard wearing characteristics, they are applied extensively in construction, marine, chemical and electrical sectors.

4. What should be done to maintain FRP gratings?

They remain useful for long and safe if they are cleaned and inspected regularly.

5. Can FRP gratings be applied for outdoors?

Yes, FRP gratings are resistant to UV radiation and can safely be installed in exposed environments.