The pet food industry is growing at a rapid pace, as pet owners show increasing concern for the quality of the food offered to their pets. This necessitates greater focus on quality control of the food pet owners are providing their pets. Packaging manufacturers of pet food work hand in hand with the production teams, therefore, it is very important to retain pet food quality. There are particular parts of the system which make the compliance to safety and quality control measures possible, The most important parts are the grinding, mixing and extrusion machines. The equipped processing of pet food has to be carried out under strict regulation requirements to guarantee the protection of public and animal health. In the following lines we will review the critical characteristics of pet food processing equipment to maintain quality control.

Quality Management System In Pet Food Production

Pets’ well-being greatly relies on quality control in the production of pet food. The quality of ingredients, processing techniques, and even the packaging of the product affect its safety and nutritional value. Inappropriate quality control can lead to contamination, nutritional imbalances, and erosion of consumer trust. For packaging manufacturers, collaborating with processors to maintain quality pet food throughout the production cycle is key to satisfying consumer demands and meeting regulatory standards. Recently, the growing need for high-end pet food has further fueled the need for stringent quality control. Safety, freshness, and nutrition are some of the core qualities consumers want in pet food. Thus, with adequate processing and quality assurance systems in place, manufacturers can meet these set standards. Moreover, enforcing strict quality control allows avoidance of expensive product recalls, protection of brand image, and sustained customer loyalty.

Features of Pet Food Processing Equipment That Ensure Quality Control

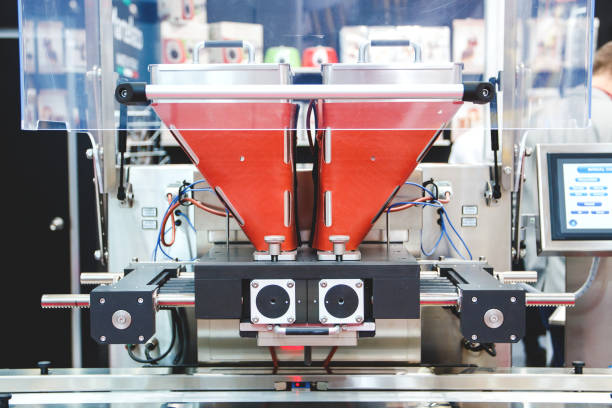

The equipment used in processing pet foods facilities has several characteristics that ensure the safety and quality of pet food prepared. An example of such a feature is precision ingredient measuring, which guarantees that ingredients which are added are done so in the correct amounts. Accurate measuring helps not only in preserving nutrition, but also in controlling allergens. The mixing and homogenization systems also automate other processes, thereby enhancing the uniformity of the texture and the distribution of the ingredients within the food both of which are essential for the texture and digestibility of the food. Another characteristic of the pet food processing equipment is the heat treatment and sterilization of the finished products. These ensure that all harmful microorganisms are destroyed and that the food is preserved effectively. Where there is food safety concern and prevention of spoilage, these provisions are essential. In modern processing equipment, the automatic quality supervising systems have also been integrated, which know the important parameters like temperature, moisture, and the consistency of the ingredients, so that if any set value is deviated from, adjustments could be done in order to maintain the required standard. Final pet food processing is done to ensure that all the pet food is packed in the right containers fully sealed and cannot be contaminated. This allows the end users to purchase the final product in the best conditions. With these features these plans can continuously provide safe products that fulfill the nutrition requirements set by specialists.

How Pet Food Packaging Producers Maintain Quality Control

They work with the pet food processors from the start and aid in identifying the proper packaging materials which can best suit the quality control systems. It helps determine the proper grade of materials for every type of pet food in a way that its freshness, nutritional value, and safety are properly contained. Furthermore, innovations like childproof closures and tamper-evident seals aid in safeguarding the products from external contamination. When we package pet food, we let pet food processors integrate the box to the production line so there is no need to manually pack the product. This greatly enhances product quality control and integrity. It is also easier to produce a large number of products within a short period of time and prevent them from being damaged during storage and transportation. It is more difficult to accomplish these processes for other types of pet food. With the increase of awareness on protecting the environment, many consumers are looking for sustainable packaging options, thus making these types of solutions very important for the modern era.

New Developments In Technology For Processing Pet Foods

Modernization is changing how pet food is processed, and pet food processing equipment is no exception. Automation and precision technology increase the consistency and efficiency in the production of pet foods. These types of technology work to achieve a high volume of production alongside stringent quality control. Artificial intelligence and machine learning are also starting to be utilized in the pet food processing industry, where they offer predictive capabilities to help manufacturers in foreseeing problems and optimizing production procedures. These innovations enable manufacturers to improve product consistency, minimize waste, and increase the safety of pet food products. Using these innovations in technology, pet food processors together with packaging manufacturers are able to achieve the highest standards of quality while meeting the ever-increasing demand from consumers for safe and healthy pet food. As technology continues to develop, pet food manufacturers will overcome high-volume production challenges while always keeping track of quality issues. There is also improved traceability, which means that every batch of pet food including its ingredients and the final product is traceable for greater transparency.

Conclusion

The food processing equipment for pets is an integral piece of machinery that guarantees the safety, quality, and brand value of the pet food products, Precision ingredient measuring, automated mixing and heating, and real-time product monitoring are some auxiliary features a piece of equipment may have. Investment in high-quality processing equipment alongside cooperation with pet food packaging manufacturers would enhance pet food safety, nutrition value, and overall appeal, addressing the expectations of the pets and their owners. The growing market for premium pet food underscores further the role of pet food processing equipment and packaging manufacturers in safeguarding quality control. It is through these sharp innovations and attention to detail that the ever-changing consumer desires are matched without compromise on the health and well-being of pets all around. This will allow manufacturers to remain competitive while meeting the expectations of consumers for guaranteed safe, high-quality, and sustainable food products for pets. This multi-faceted approach ensures that with every stride made pet dogs are provided for, the need for higher quality control standards and healthier food alternatives are received with open arms. These measures will let the industry experts anticipate the expectations and surpass them in helping pets as well as pet owners.