Have you ever been involved in a project that had a design detail that looked perfect on paper yet was impossible to construct in the field and caused delays, expensive change orders, and strained coordination meetings with project teams? If yes, you are not alone.

The construction industry operates like a symphony of specialists — architects, structural engineers, MEP designers, contractors, and fabricators. With even the slightest confusion or miscommunication potentially leading to mistakes, rework, and huge budget overages. This is where Shop Drawing Services can be a game-changer. Shop drawings are more than just technical documents; they provide architects, engineers, contractors, and fabricators with a common language that translates the design intent of the drawing into precise, buildable detail, which helps engage stakeholders throughout the project from the conception phase to occupancy.

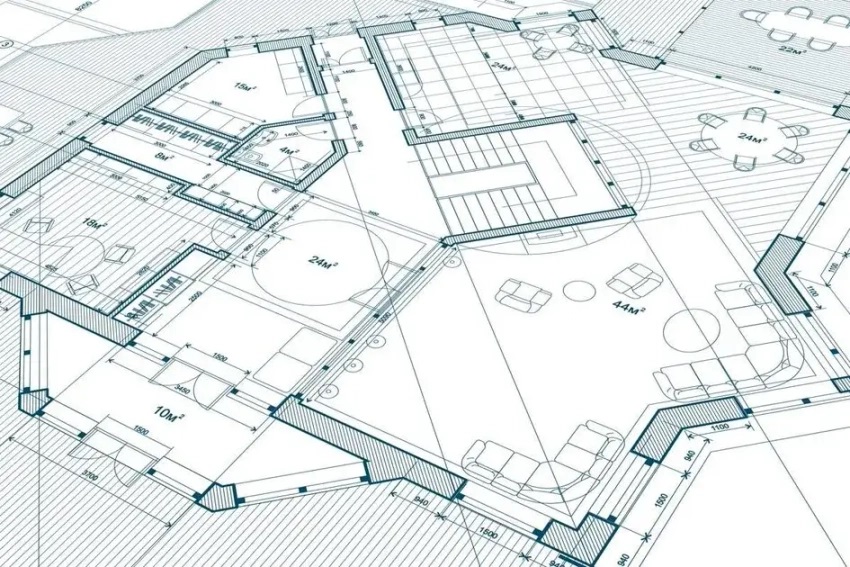

Let’s Understand, What Are Shop Drawings?

In the building process, shop drawings are the essential connection between design and construction. Whereas design drawings outline ideas, shop drawings contain the details that illustrate how to fabricate the components of the overall construction. As-built drawings would describe the final construction conditions.

Key features of shop drawings include:

- They provide exact dimensions, materials, and details related to the installation.

- They convert the design intent into usable information for construction.

- They note connections, joints, clearances, and coordination considerations.

- They include additional features that are not included in architectural drawings to establish constructability and accuracy.

Project teams that use Shop Drawing Services:

- Architects and designers for design confirmation.

- Contractors for installation criteria.

- Fabricators for manufacturing criteria.

- MEP engineers for project coordination.

- Owners for review and confirmation of quality.

Shop drawings connect intention and action so that every piece is accurate to the original design and can be built.

Common Communication Challenges in Construction Projects

Construction projects are complicated, consisting of multiple stakeholders with varied backgrounds and skills. One common occurrence in the construction industry is miscommunication, causing project delays and cost overruns.

- The complexity of interpreting the design intent typically leads to interpretations, especially when translating the design from concept drawings into constructed work.

- When architects, engineers, and contractors are not aligned, conflicting assumptions or misinterpretations can cause coordination issues.

- Errors resulting from incomplete or vague documentation can lead to rework and resource waste.

- Late clarification is costly delays that can derail schedules, increasing time and money risks.

This is where shop drawings come into play. Shop drawings will give clear, fabrication-level detail that standardizes communication and minimizes ambiguity. They ensure that stakeholders from designers to fabricators are on the same page.

How Shop Drawings Enhance Stakeholder Communication

In construction, the act of communicating is not simply providing information, but rather ensuring that all parties involved understand information the same way. This is where Shop Drawing Services significantly assist construction, as they take design concepts and convert them into data on construction documents, which removes ambiguity.

Clear Understanding of Design Intent:

Shop drawings take a concept of design and abstract it into specific details that can be constructed. For example, instead of providing schematics in the architectural plans for steel connections or HVAC duct routing, contractors will get exact specifications. This enables the fabricator or installer to have the dimensions, materials, and tolerances needed to work confidently.

Standardized Reference for All Stakeholders:

Shop drawings can be utilized as a single source of truth. By putting everything into one standardized set of drawings, it has the potential to eliminate misinterpretations. Everyone, from the architect reviewing finishes to the subcontractor conducting work in the field, is referencing the same set of documents for their work.

Better Coordination Between Disciplines:

One of the most powerful aspects of shop drawings with Architecture 3D BIM Modeling is the ability to identify clashes between architectural, structural, and MEP systems during the drawing process. For example, shop drawings will help to identify a structural beam in conflict with an air duct, allowing for adjustment to either the duct or beam prior to construction and saving valuable time and costly adjustments in the field.

Faster Decision-Making & Approvals:

Shop drawings serve as a tool for clarification, minimizing back-and-forth communications in the decision-making process. Owners and designers can review the available options and allow for quick approvals, keeping the project on schedule. For instance, layouts for furniture or types of façade systems can be approved in advance to create less ambiguity in the field.

Accountability and Record Keeping:

Finally, shop drawings also create a documented transaction around approved details. This helps to keep stakeholders accountable and can protect team members, whether Architect or Contractor, in case disputes arise. For Contractors, once they have a shop drawing approved, they can proceed with work that corresponds with design and owner expectations.

By bridging the gaps across disciplines, Shop Drawing Services enhance communication, accelerate coordination, and provide common ground for stakeholders on a project.

Best Practices for Effective Shop Drawings

For shop drawings to be effective, they must be produced with accuracy and consistency. Following best practices helps ensure they serve as an effective communication tool throughout the project life.

- Use standard formats and symbols, so there is consistency across disciplines.

- Ensure that your annotations and dimensions are clear in enough detail, so the contractor and fabricator can differentiate meaning easily.

- Use 3D BIM Modeling to produce intelligent, clash-free shop drawings that better facilitate visualization and coordination.

- Enable cloud-based sharing tools, so that updates can be made in real time and avoid lag time in communicating these changes.

- Conduct frequent reviews and approvals at every stage for constructability and compliance.

By implementing these practices, shop drawings transform from static documents into dynamic instruments that facilitate alignment and efficiency in construction.

Conclusion

Effective communication is the backbone of successful construction projects, driving all stakeholders towards the same goal. Shop Drawing Services act as a universal language for all stakeholders by breaking down the design intent into detailed, buildable documents. The benefits are obvious -better accuracy, less errors, lower rework, better teamwork, and substantial cost savings. In today’s fast-paced construction environment, we can no longer rely on assumptions. AEC firms need to adopt a detailed and collaborative shop drawing workflow in order to future-proof their projects and deliver with certainty, quality, and efficiency.