I’ve watched too many small business owners struggle with printing their designs. They either pay way too much for screen printing setups or deal with faded prints that look terrible after a few washes. Custom DTF transfers changed all that. They work on pretty much any fabric you throw at them and the colors actually stay put. If you’re trying to figure out the best way to get your designs onto shirts, hoodies or whatever else you’re selling, DTF is worth your attention.

What Are DTF Transfers?

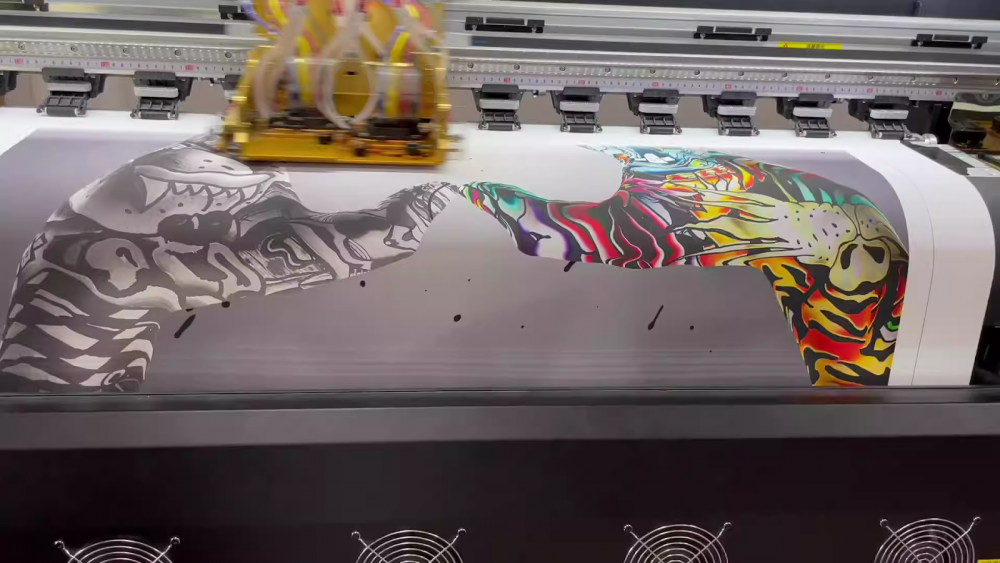

DTF stands for Direct to Film. Here’s how it works: your design gets printed onto a special film. Then powder adhesive gets sprinkled on top and heated. When you want to use it, you just press it onto your shirt with heat.

What makes DTF different? It sticks to everything. Cotton, polyester, those weird cotton-poly blends, even leather if that’s your thing. Screen printing needs separate screens for each color. DTG printers only really work well on cotton. DTF just works.

I’ve seen startups use DTF because they can order exactly what they need. Five shirts for a pop-up shop? Sure. Five hundred for a big event? No problem. The transfers sit in a drawer for months without going bad.

Selecting Quality DTF Transfers

Here’s the thing about DTF transfers: the cheap ones look cheap. I’ve seen transfers where the colors looked muddy or the adhesive didn’t stick evenly. You can actually see bare patches where the powder missed.

Good transfers have rich, deep colors. Not that washed-out look you get from bad printers. The adhesive should cover every bit of your design smoothly.

How long do they last? That’s the real question. I’ve tested transfers that started peeling after ten washes. The good ones go through fifty washes and still look fresh. Always ask suppliers how their transfers hold up.

Need something different? Check out options like color reflective transfer by Mad Monkey. These look totally normal during the day but light up when headlights hit them. Perfect for running gear, kids’ jackets or anyone working near traffic.

The film itself matters too. Good film peels off clean. Bad film tears or leaves sticky residue on your design.

Choosing a DTF Transfer Supplier

I learned this the hard way: your supplier can tank your whole operation. Some ship next day. Others take two weeks and won’t tell you why.

Test their customer service before you order. Send them an email with questions. Do they actually respond? Are they helpful or just trying to close the sale? You want someone who picks up the phone when your transfers arrive wrong.

Reviews matter but read between the lines. One bad review happens. Ten reviews complaining about the same problem? That’s a pattern.

Always order samples first. I don’t care how good their website looks. Order a few transfers and actually use them. Wash them five or six times. See if the colors match what you expected. Feel the quality.

Don’t just pick whoever’s cheapest. I’ve replaced entire orders because I went with the low bidder. That “savings” cost me way more in refunds and angry customers.

Ensuring Color Accuracy

Colors on your screen lie to you. That bright red you see? It might print as orange-red or burgundy.

Use CMYK files, not RGB. RGB is for screens. CMYK is for printing. This one switch fixes half your color problems.

Pay for a color proof. It’s maybe ten or fifteen bucks extra but you’ll know exactly what you’re getting. Some colors are just hard to print. Bright neons, certain purples, really vibrant oranges. They never look quite like your screen. Talk to your supplier about problem colors before you order three hundred shirts.

Keep samples from orders that came out right. When you reorder, you can compare the new batch to your saved sample.

Enhancing Brand Identity with DTF

DTF lets you print stuff that’s impossible with other methods. Gradients that fade smoothly. Photos that actually look like photos. Tiny text that you can still read.

White ink is huge. You can print light designs on black shirts and they actually show up bright. Other methods make light colors look dingy on dark fabric.

Your logo should look identical whether it’s on a navy hoodie or a white tank top. DTF makes that happen. I’ve seen brands struggle because their logo looked different on every product.

You can print anywhere too. Chest, back, sleeves, wherever. Create matching sets where everything has the same design quality.

Conclusion

DTF transfers work because they’re flexible and they last. You don’t need expensive equipment or huge minimum orders. Find a supplier who actually cares about quality. Order samples and test everything before you commit. Build a real relationship with your vendor so they know your standards. When you get the right DTF setup going, you’ll finally have merch that looks as good as you imagined it.