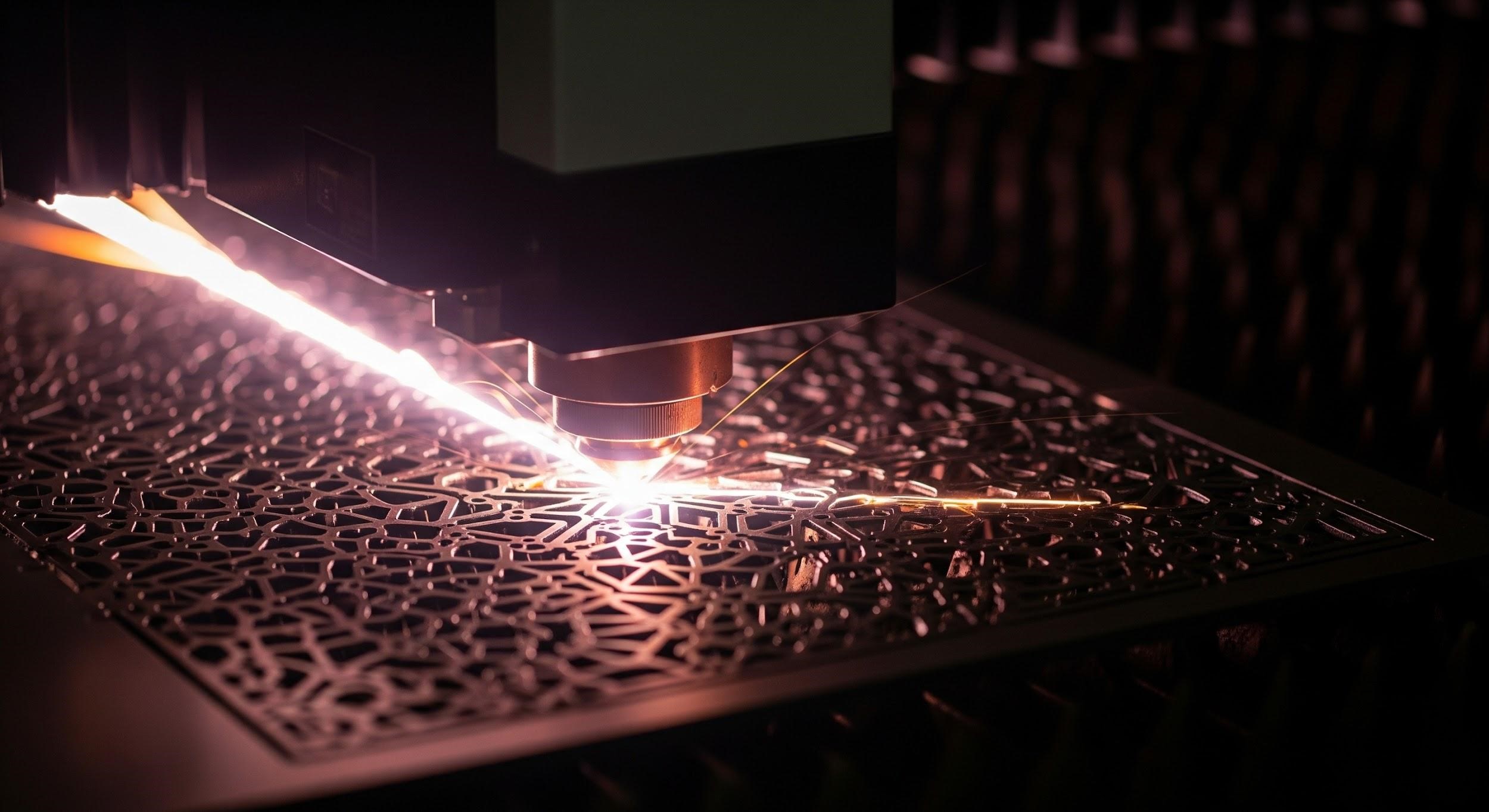

Laser cutting is no longer just a cutting technique for industrial parts. It’s now used by designers, artists, small businesses, and hobbyists to create home decor to customized packaging. Individuals are not only choosing what they wish to create, but also what materials they’d like to work with.

Local design trends show a firm trend towards material that is functional, environmentally friendly, and visually appealing. Whether designing in a downtown studio or Scarborough workshop, material choice is everything.

Plywood: The Hot Favionorite for Custom Construct

Plywood continues to be one of the go-to choices for laser cutting jobs in Toronto. It’s inexpensive, readily available, and easy to cut through. It’s locally used to make furniture, signs, wall art, and a host of other things. Its smooth finish and natural look are perfect for modern or rustic designs.

Toronto retailers prefer using birch plywood because it has a plain texture and consistent quality. Even most designers paint or stain it after it’s been cut for a unique finish.

Why plywood is now so popular:

- Easy to cut with clean edges

- Lightweight but strong

- Available to purchase in a range of thicknesses

- Perfect for home as well as commercial projects

Acrylic: Bright, Bold, and Perfect for Brands

Acrylic is also a favorite of Toronto businesses that wish to be seen. Plastic like this comes in clear, solid, or even mirror finishes and is ideal for signs, display cases, and awards. Laser cutting makes it easy to create sharp edges and shiny finishes.

Downtown design studios mostly use acrylic for window displays or brand materials. It is also waterproof, so it can be used indoors or outdoors.

- The reasons why acrylic is a preferred option:Rich, professional sheen

- Vibrant, high-shine colors

- Weather-resistant, durable

- Perfect for engraving and cutting intricate designs

Stainless Steel: Perfect for Long-Lasting, Modern Uses

Stainless steel is used in Toronto industries that vary from construction to custom interiors. While more energy is required to cut stainless steel than wood or plastic, laser cutting has no problem handling it.

Stainless steel is applied in signage, stair railings, panels, and hardware. Laser-cut stainless is commonly used by the tech and restaurant industries of Toronto for clean design features that withstand years.

Why it’s so well-liked:

- Resistant to corrosion and rust

- Low maintenance and long-lasting

- Has a modern, industrial aesthetic

- Ideal for both outdoor and indoor applications

MDF: Inexpensive and Ideal for Prototyping

Medium-density fiberboard, or MDF, is a pressed wood item that’s easy to handle and smooth to the touch. Toronto makers adore it for prototyping new designs or working on cheap projects.

Many makerspaces use MDF to make display models, decorative boxes, and multi-level wall art. Because it’s cheaper than hardwoods, it’s ideal for prototyping ideas before spending money on more expensive materials.

Why MDF is a first-choice material:

- Very cost-effective

- Easy to paint or finish

- Ideal for fine cuts

- Cut from large sheets

Cardboard: Eco-Friendly and Maker-Friendly

Cardboard might seem like a straightforward material, but it’s a hit among Toronto’s growing maker community. Cut cardboard from a laser cutter is widely used as a prototype, package sample, and even 3D art.

Simple to cut, light to handle, and found at any supply outlet. Because it’s recyclable and biodegradable, it fits Toronto’s growing emphasis on green materials.

Benefits of cardboard:

- Low cost and easy access

- Perfect for model making

- Fully recyclable

- Efficiently cuts with little power

Cork: Natural Appearance With a Gentle Touch

Cork is becoming more popular in 2025 with those who desire to craft customized coasters, wall panels, or desk organizers. This soft and flexible material is readily cut with lasers and produces minimal smoke.

Among Toronto’s design population, cork is being used more and more for functional as well as aesthetic applications. Its natural texture adds warmth to spaces, and it pairs well with wood or metal decor.

Why cork is picking up steam:

- Natural and renewable

- Soft touch for home goods

- Lightweight and silent

- Adds an organic touch to designs

Fabrics: A New Creative Layer

Laser cutting is also done on fabrics nowadays. Felt, denim, and synthetic materials in Toronto’s fashion and interior design communities are being cut with precision.

Designers are using lasers to create designs, labels, and even art on clothing. Since the laser melts the seams when it cuts, there is no fraying. That’s a big plus for clean and stylish results.

Fabric-friendly advantages:

- Scissor-free clean cuts

- Ideal for fine details

- Ideal for fashion and interior décor

- Clean cuts with no strings to hold them back

Bamboo: Strong, Chic, and Green

As sustainability becomes increasingly popular in Toronto, bamboo has become a front-runner as a laser cutting material. It’s actually stronger than most softwoods but still laser cuts well.

The smooth surface and natural texture of bamboo make it a natural choice for engraved signs, kitchen tools, or decorative panels. Eco-friendly product lines in most local boutiques feature bamboo.

Why it stands out:

- Environmentally friendly and fast-growing renewable

- Clean cut is strong

- Stunning grain for a natural appearance

- Gifting and custom items are trending

Keeping with the Trends, Choosing What Works

Toronto’s laser cutting culture in 2025 is more creative than ever. Whether a small business manufacturing products, an artist building an installation, or a startup testing ideas, material choice makes the final product.

There’s no single greatest material for all. The best choice relies on the project, budget, and aesthetic. Local trends indicate, however, that Torontonians have a weakness for materials that are simple to use, earth-friendly, and aesthetically pleasing.

Final Thought: Cut Smart, Build Better

Laser cutting brings prospects for innovation, efficiency, and precision. With Toronto’s growing market, laser cutting Toronto is becoming essential for companies and artists who want to stay ahead. From plywood and acrylic to cork and bamboo, 2025 is the year to break boundaries and bring new ideas to life.