Hey, what’s up? I’m your friendly HVAC nerd from Adhunik Powertech. Been doing this gig for two decades now—yeah, that’s a lot of summers, a lot of server rooms, and more “my AC isn’t working!” calls than I can count. In that time? HVAC tech’s gone from clunky old dinosaurs to some pretty wild, smart systems. Honestly, a lot’s changed, but one thing’s stayed the same: we’re obsessed with nailing the basics and keeping our clients comfy (and not broke).

Let’s pull back the curtain a sec. Want to know how we keep things running cool, efficient, and 100% not a sweatbox? Here’s the not-so-secret sauce:

How We Actually Design HVACs That Work

Look, slapping a big metal box in a room and hoping for the best? That’s amateur hour. Real HVAC design is like a weird mix of math, common sense, and a little black magic.

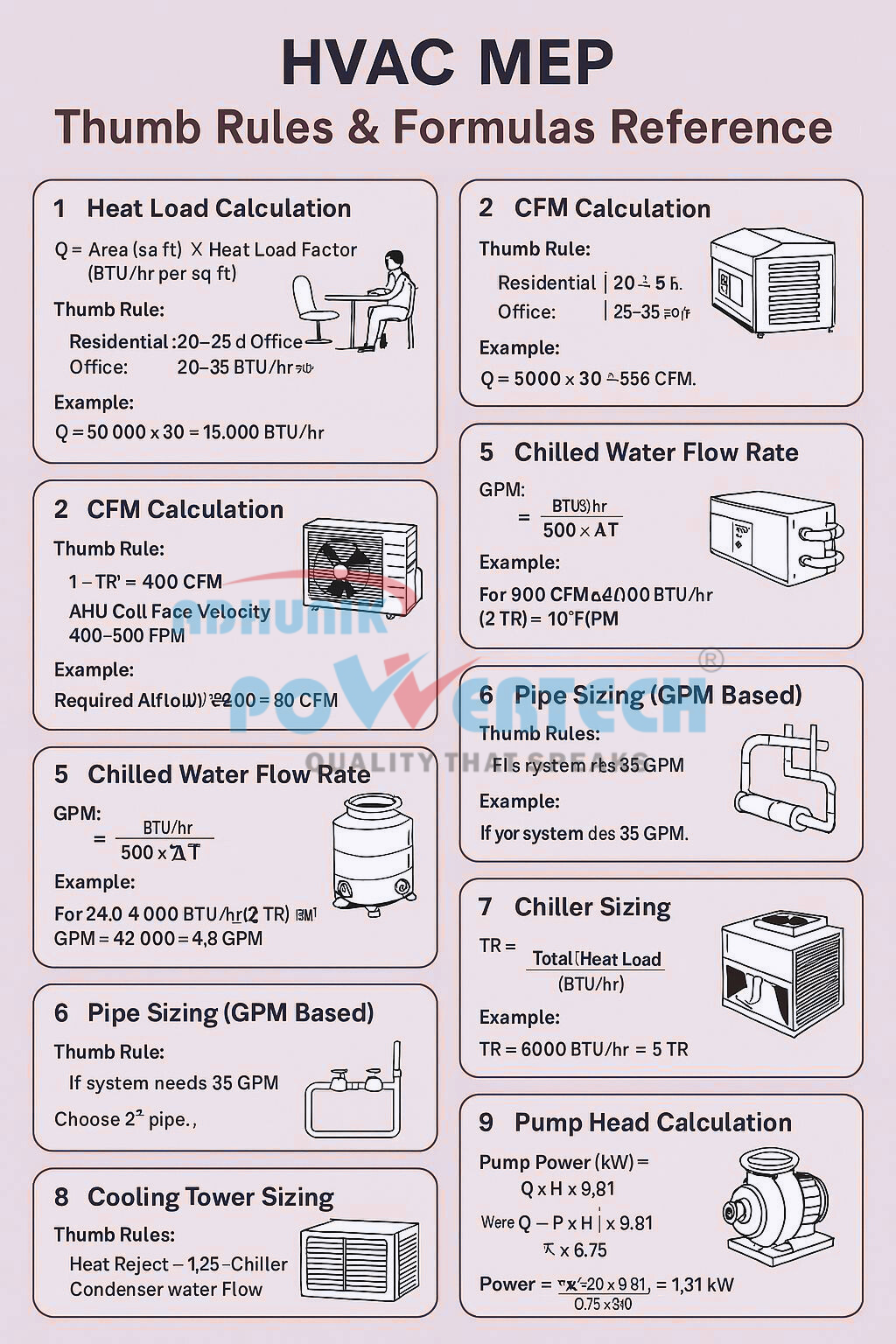

First up—Heat Load. You gotta know how much heat’s getting dumped in a room before you can cool it. We use this formula: Q = Area × Heat Load Factor (in BTU/hr per sq.ft). So, say you’ve got a 500 sq.ft office and you need 30 BTU/hr per sq.ft. That’s 15,000 BTU/hr, or about 1.25 Tons of Refrigeration (TR). Oversize it and you waste money. Undersize it and you’re sweating through your shirt. Nobody wants that.

Next: Airflow. CFM (Cubic Feet per Minute). It’s what keeps the air moving. We do some quick math: CFM = Sensible Heat (BTU/hr) ÷ (1.08 × Delta T). Boring? Maybe. But it works. A standard rule—1 TR is about 400 CFM. Yeah, sometimes we guesstimate early on, but we double-check before you end up with a wind tunnel in your office.

Chilled Water Flow Rate. This is like the blood in your cooling system’s veins. We calculate GPM (Gallons Per Minute) with: GPM = BTU/hr ÷ (500 × Delta T). Example: 24,000 BTU/hr, 10°F temp drop? That’s 4.8 GPM. Keeps things efficient and chill (literally).

Chiller & Cooling Tower Sizing. Here’s where people mess up big time. Too small, you’re toast. Too big, you wasted your cash. We figure out chiller size with TR = BTU/hr ÷ 12,000. 60,000 BTU/hr? That’s a 5 TR chiller. Cooling towers? They gotta handle more than the chiller load—so we bump it up: Heat Rejection ≈ 1.25 × Cooling Load.

Duct & Pipe Sizing. Think of these as the arteries and veins. Too skinny, and nothing flows; too big, and you’re wasting money. We stick to good velocity ranges: 1400–1800 FPM for air ducts, 3–12 ft/sec for chilled water pipes. Don’t overthink it, but don’t ignore it either.

Critical Environments: Where the Stakes Are High

Now, we don’t just do comfy offices. We’ve got big experience with hospitals, pharma cleanrooms—places where “oops” isn’t an option. Here’s what that looks like:

Clean Room Classifications & ACH (Air Changes Per Hour). We don’t mess around—ISO 14644-1, GMP, all that jazz. More air changes means fewer nasties floating around. Some quick numbers:

– Operation Theaters: 20–25 ACH

– ISO 7 Cleanrooms: 60–90 ACH

That’s a TON of air moving, and it’s gotta be filtered like crazy.

HEPA Filters. These are the bouncers at the club—nothing nasty gets past them. 99.97% efficiency at 0.3 microns, which is…tiny. Each 24″x24″ filter can handle about 500 CFM. Do the math, or call us—we’ll do it for you.

Pressure Differentials. You want clean rooms to stay clean? Keep the pressure higher inside than outside. For isolation rooms, flip it—keep the germs in. Typical numbers:

– Positive: OTs (+10 to +15 Pa), ICU/NICU (+5 to +10 Pa)

– Negative: Isolation rooms (-10 to -15 Pa)

It’s not rocket science, but it’s close.

Laminar Airflow & Environmental Control. Sometimes you need a literal air shower, like above operating tables—90±20 ft/min airflow, super steady. Plus, we’re sticklers for temp and humidity:

– OTs: 21–24°C, 50–60% RH

– Pharma Cleanrooms: 20–22°C, 45–55% RH

If you don’t hit those marks? Well, enjoy your lawsuit (just kidding…sort of).

Real-World Wins

Look, it’s one thing to talk the talk. We’ve spent 20 years walking the walk—hospitals, pharma plants, crazy server rooms. We’ve seen it all, fixed it all, and yeah, sometimes saved the day when someone else messed up. That’s just what we do.

How We Actually Gets Stuff Done

Alright, let’s skip the boring corporate spiel and get to the real stuff. Adhunik Powertech’s been in the game for 20 years, and yeah, we’ve got some wins to show for it.

Gurugram’s Hot Mess, Fixed

Picture this: flashy commercial tower in Gurugram, but their energy bills? Sky-high. The AC game? Wobbly at best. So, we rolled in, did a geeky energy audit, and dropped in a fancy Variable Refrigerant Flow (VRF) system. Tweaked the ductwork, sorted out airflow—bam. Suddenly, the building’s burning 25% less power on HVAC, and the bean-counters are actually smiling for once.

Hospital Air That Doesn’t Suck

Hospitals are supposed to be clean, right? Turns out, that’s harder than you’d think. A big-shot multi-specialty hospital in Delhi needed their new surgery wing to be, like, NASA-level sterile. So we built them a tricked-out HVAC setup: multiple filtration stages, hardcore HEPA filters for every OT, and air pressure so precise you could probably levitate a ping pong ball. ISO 7 compliance? Nailed it. Fewer post-op infections? You bet.

Pharma Plant, Zero Chill Allowed

Now, try keeping a pharma plant in Hyderabad at 21°C and 48% humidity, barely budging even 2%. Not easy. But we pulled it off. The place runs like clockwork, their product stays rock-solid, and those international regulators? No complaints.

Twenty Years of Not Messing Around

Look, we’re not here to just sell you some metal boxes and bounce. Every project’s got its own quirks, and we’re all about cracking the code—whether you’re sweating in an office tower or running a lab that can’t afford a speck of dust. We’ve got the tech, the brains, and, honestly, the stubbornness to make sure you get what you actually need.

We’re about partnerships, not just paychecks. Want lower bills, smoother operations, and a workspace that actually works for you? You know where to find us. Hit us up for a free consult—let’s see what 20 years of sweat and smarts can do for you.